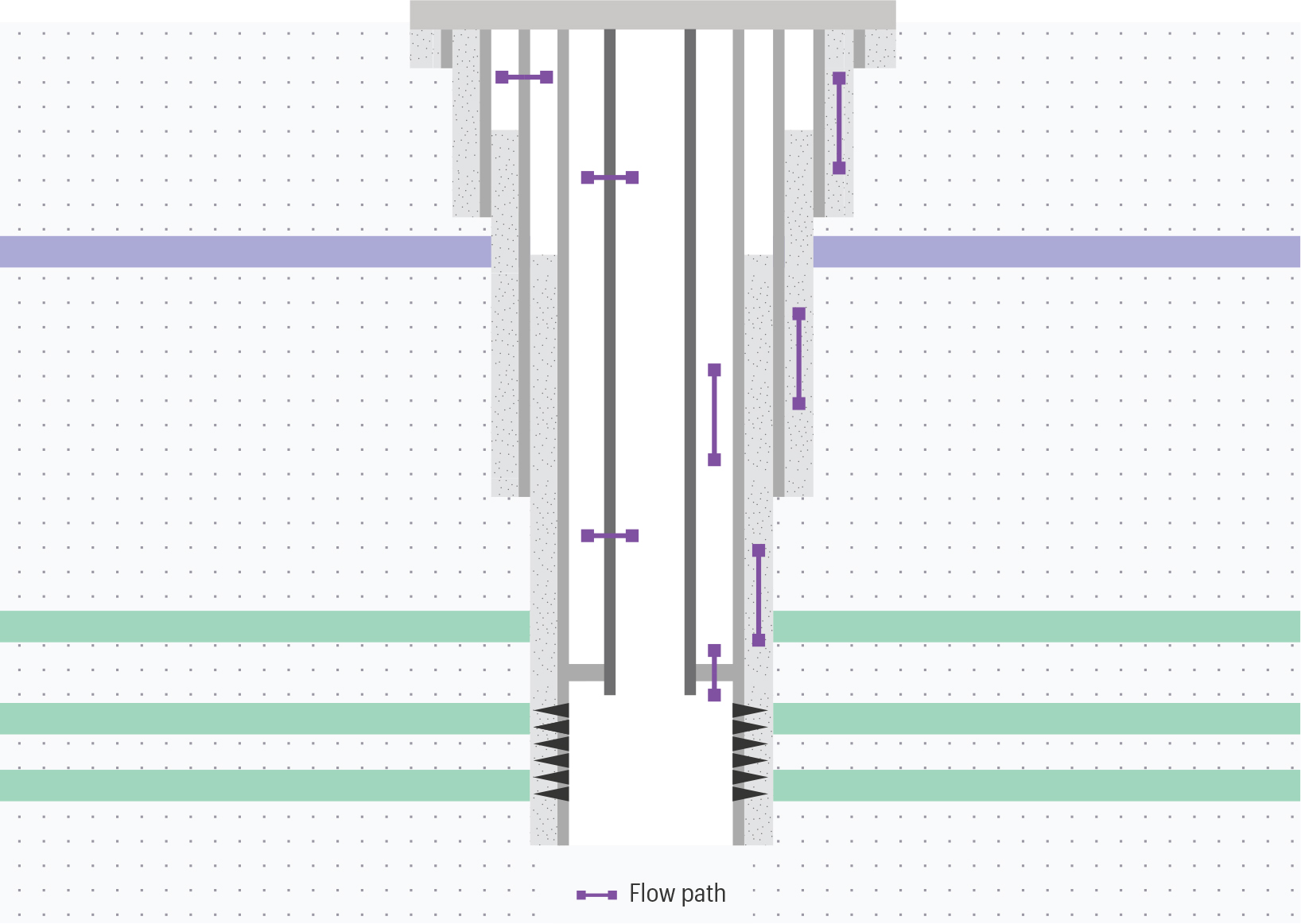

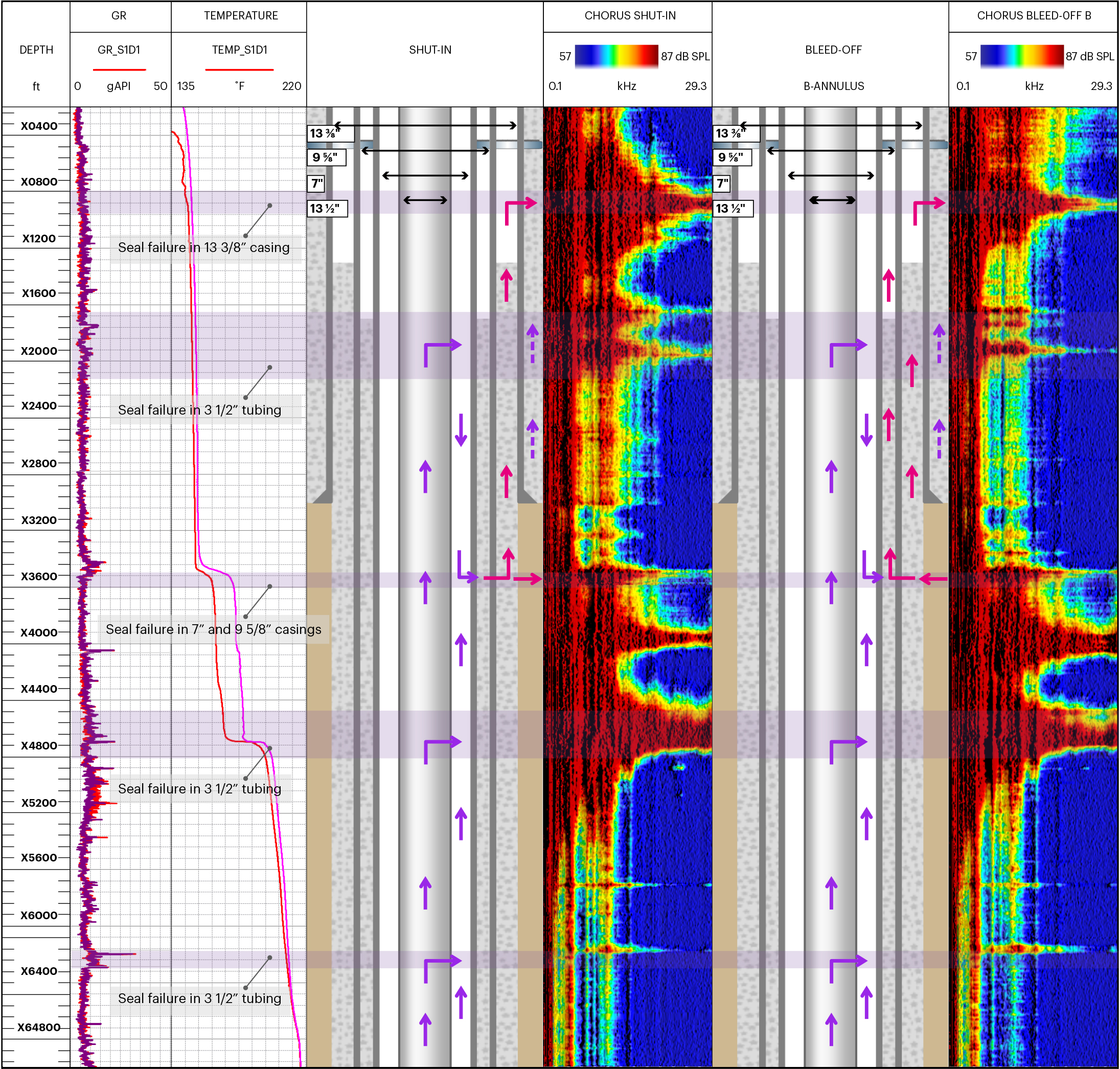

A 60-year old well in the Chadar field, Libya was exhibiting a leak at surface and sustained pressure in all three annuli – A, B and C. The age of the well coupled with the symptoms suggested a complex multi-barrier failure scenario that needed to be diagnosed quickly and accurately so that the well could be secured safely.

- Location Libya

- Customer Zallaf

- Field Chadar

- Well Type Oil producer

-

Eliminated uncontrolled release of fluids

-

Avoided further pollution and safety hazards

-

Enabled safe and secure P&A of a 60-year old well

-

Comprehensive diagnosis of complex barrier failure scenario