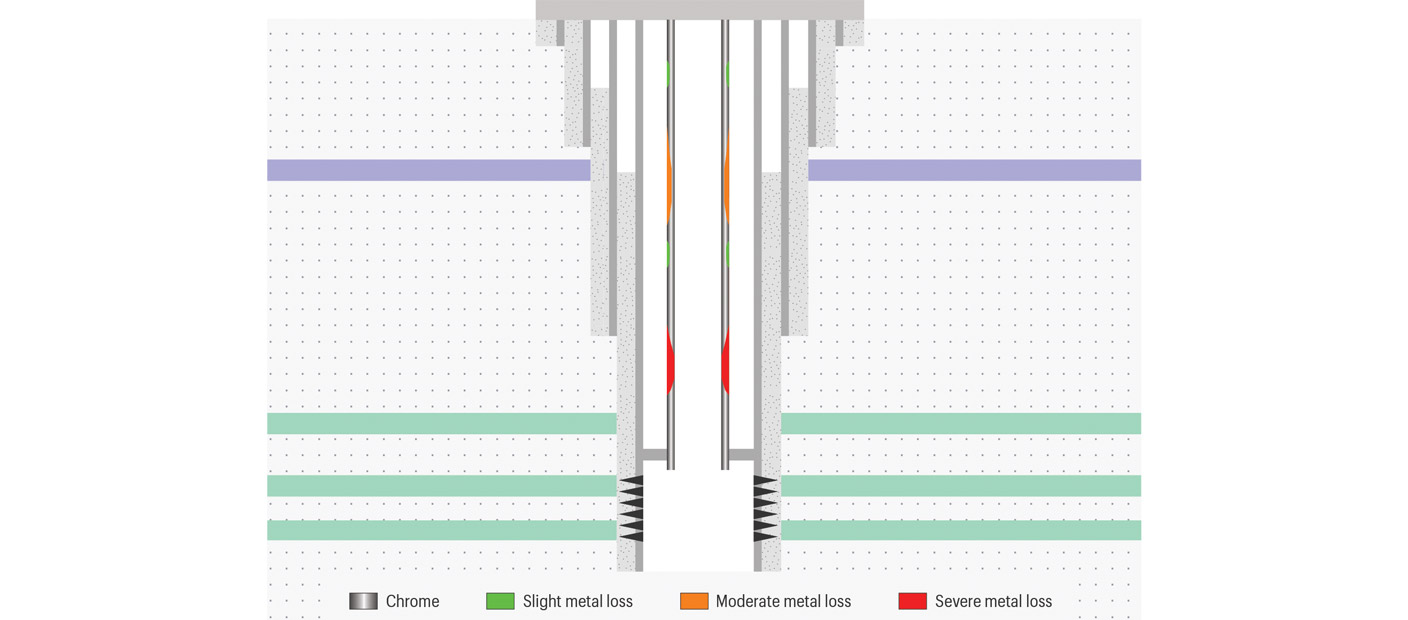

Corrosion resistant materials like chrome help protect well completions from highly-corrosive fluids. But high chrome content can cause serious problems for ordinary electromagnetic pipe inspection systems.

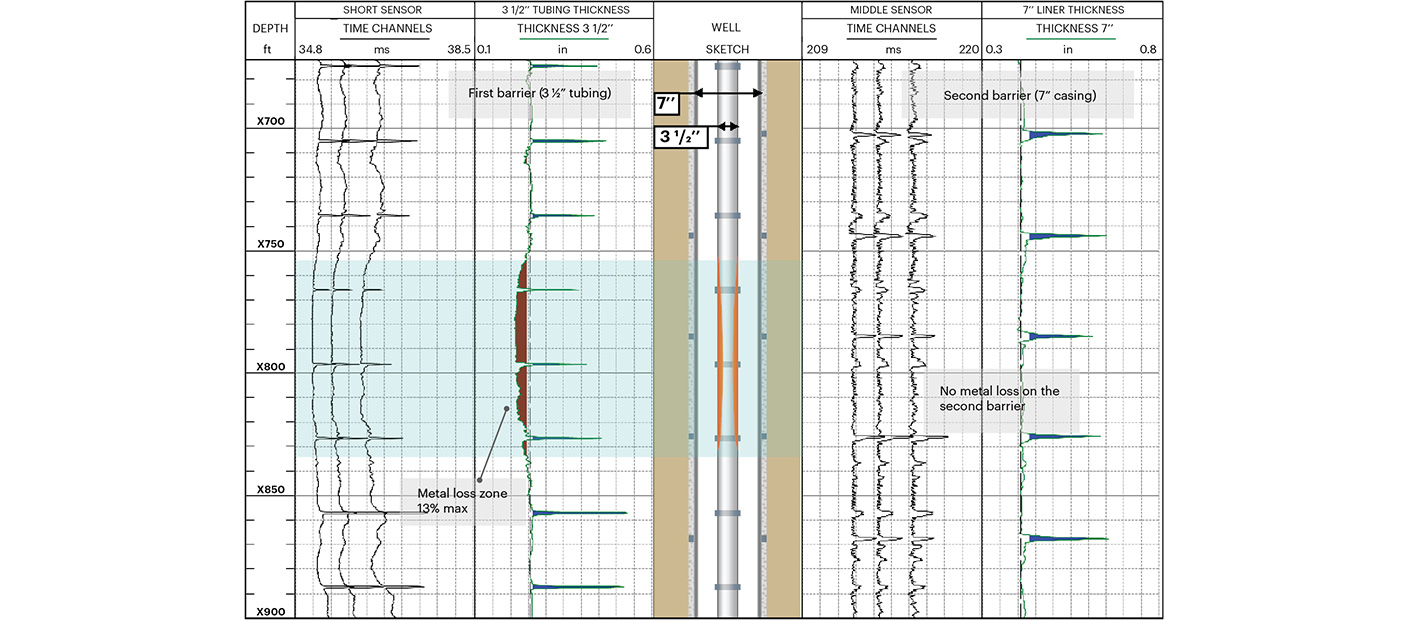

Chrome Tube Integrity provides an accurate barrier-by-barrier assessment of tubulars containing chrome or corrosion resistant alloys (CRAs).

Powered by our True Integrity system using the Pulse (electromagnetic) platform; Chrome Tube Integrity delivers accurate wall thickness data where other products fall short.

Chrome Tube Integrity, if used routinely, can support your ongoing integrity management programme, or in a targeted fashion to investigate a specific integrity breach.

Its ability to work with CRAs means that the answers are just as reliable as with conventional steel tubulars.