Backed by proven academic theories, R&D investment and years of experience, our quest to reveal a greater truth about the well system is the cornerstone of our commitment to the TGT diagnostic system approach.

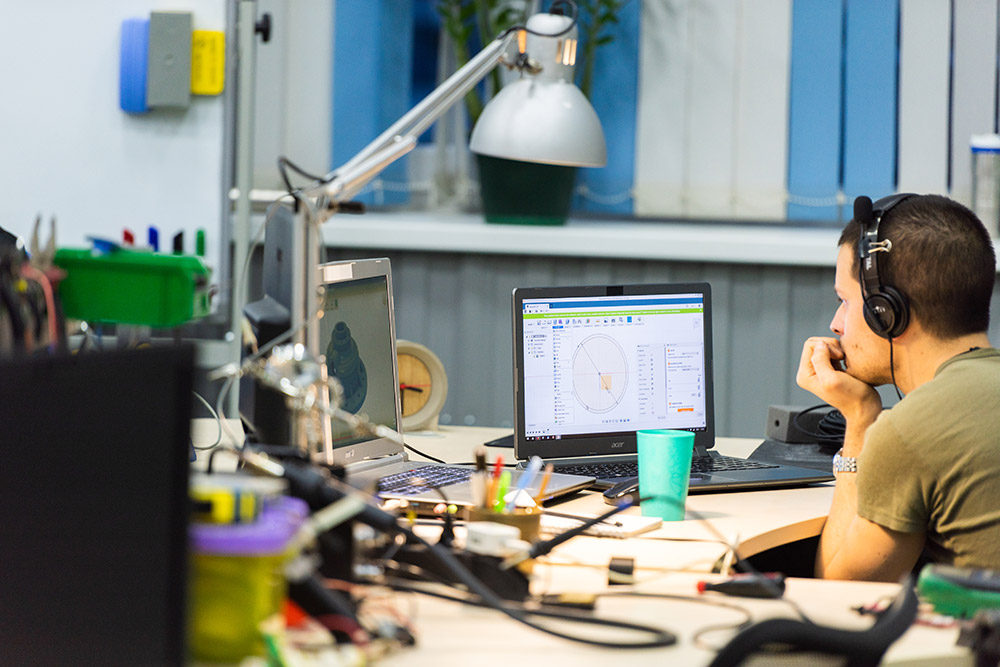

Our in-house expertise sets us apart. Our innovation process incorporates: programme design and data acquisition methodology, tool and sensor manufacturing, software development to process and model the raw data, and data interpretation by a dedicated team of well log analysts. We are unique in what we offer our clients.