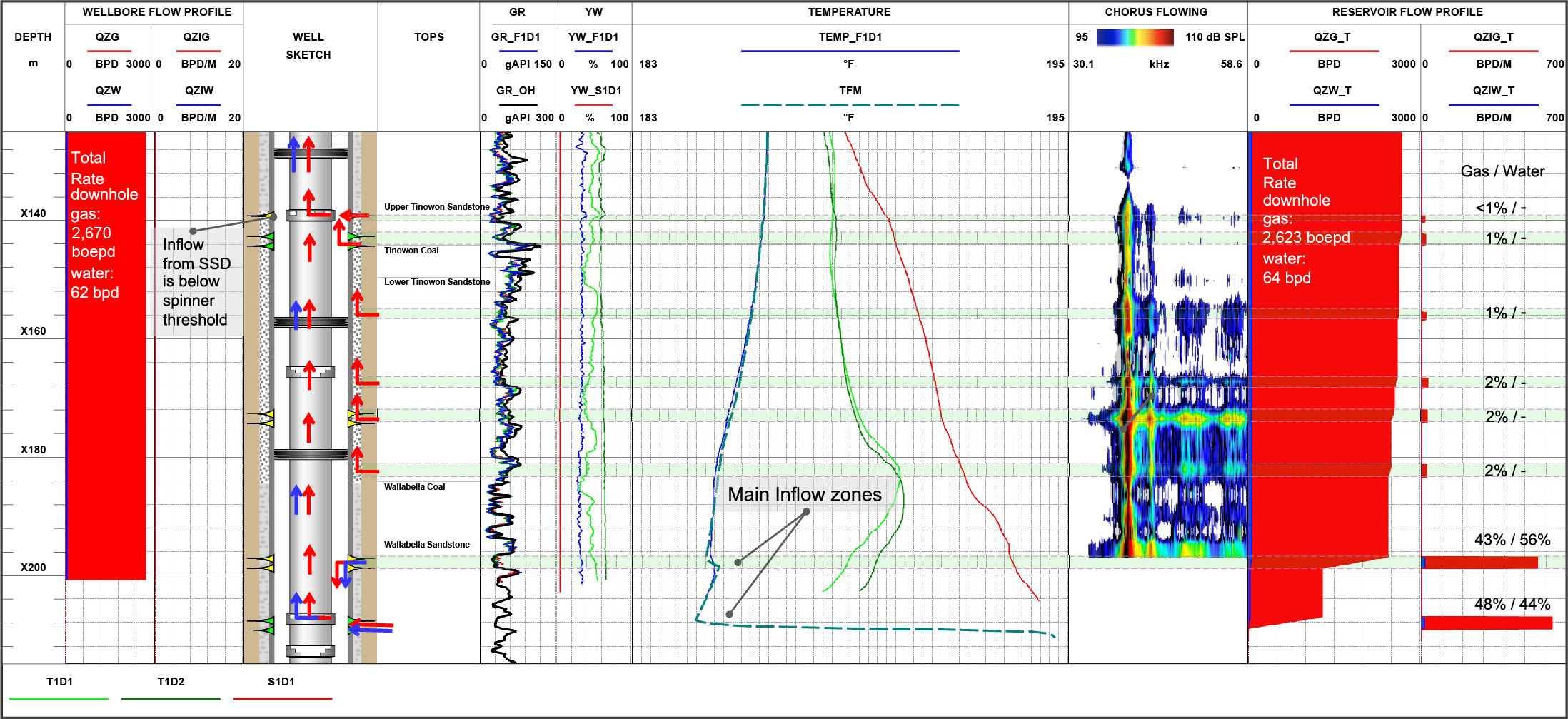

The subject well was not reaching its planned gas production rate, so the field operator wanted to investigate the issue and identify the root cause. The assumption was that both the hydraulically fractured reservoir zones were contributing to production, thus the first task was to assess the relative contributions of gas from each layer. Water production was also an issue and can be a critical problem in a gas well. The second challenge was, therefore, to identify where water was entering the well in order to plan a workover operation.

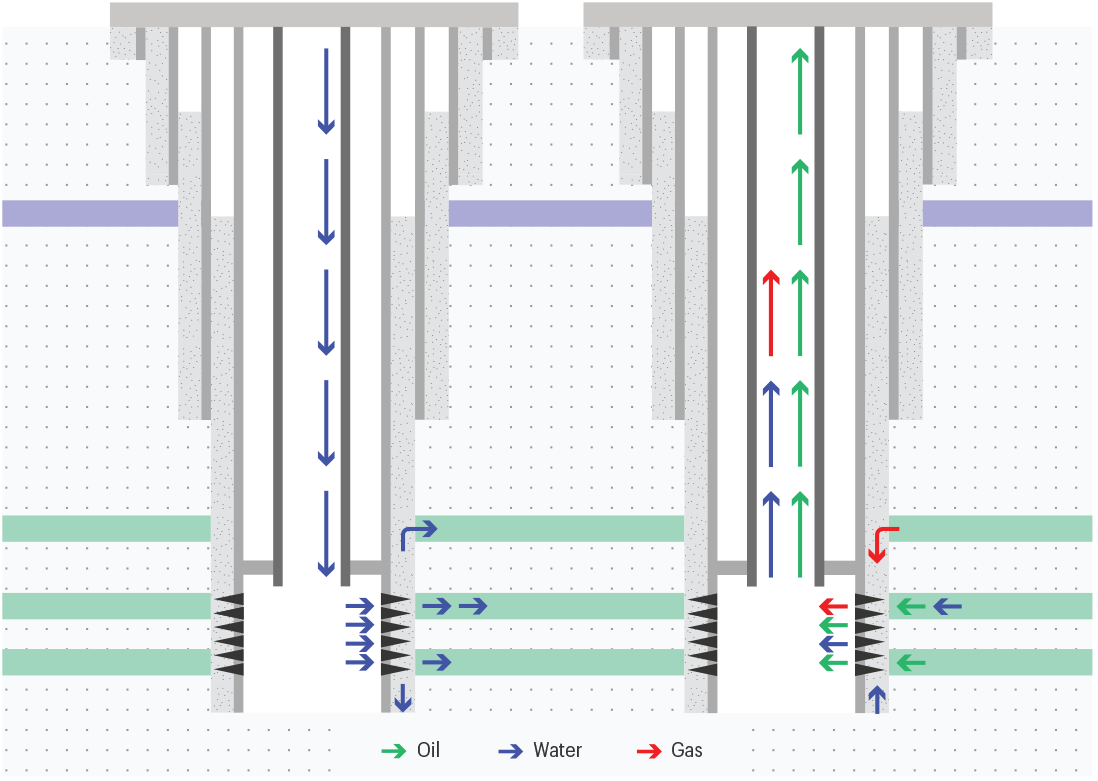

The tubing installed in this gas producer well extends below the bottom perforation interval, which means that conventional production logging tool surveys cannot help with evaluation.