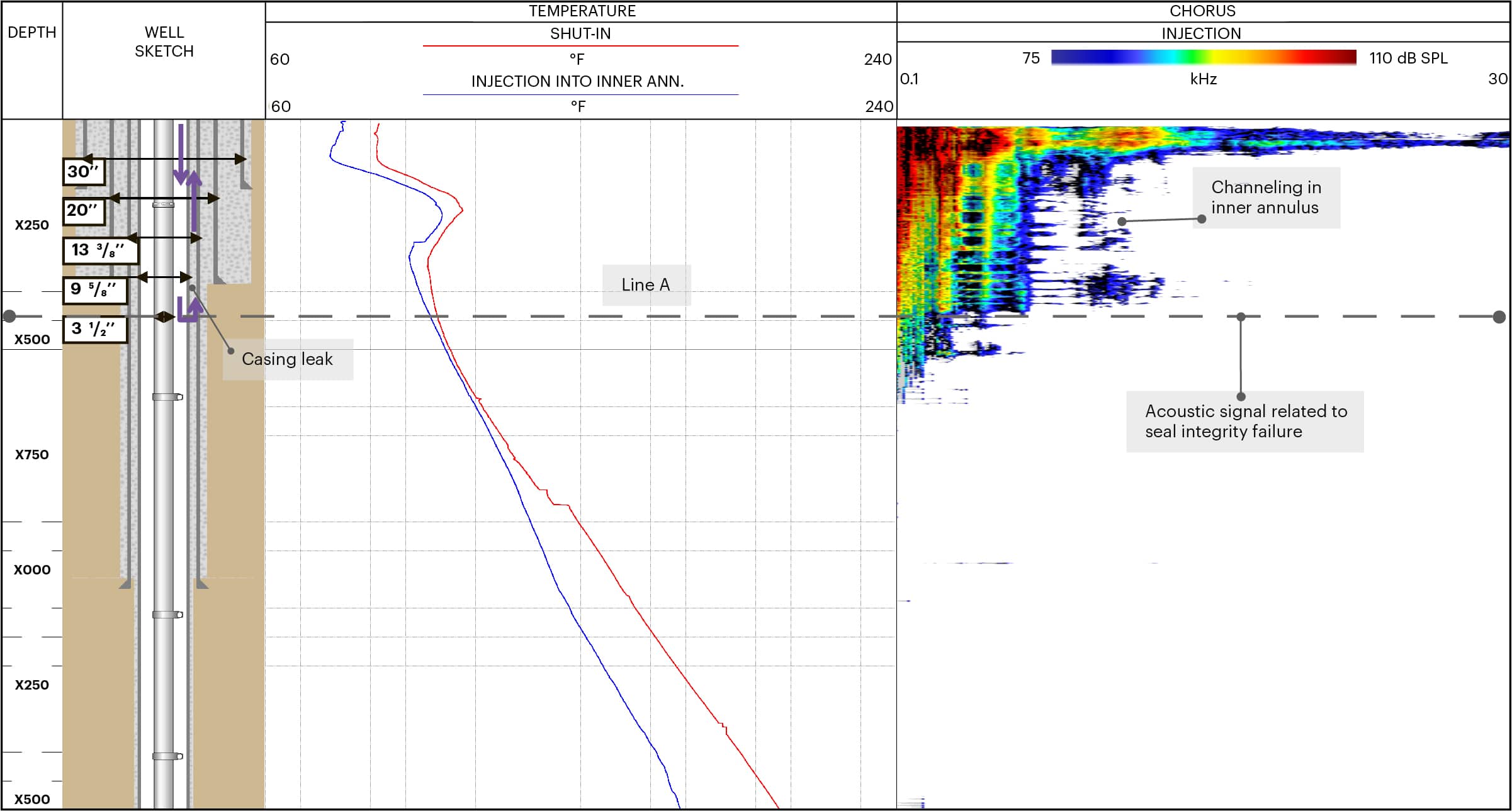

In India, approximately $1.2 billion is lost per day due to well integrity issues. A major operator performed a gas lift on a newly drilled well to initiate production but when the sustained annulus pressures (SAP) raised to alarming levels in nearby well systems, all wells had to be shut in resulting in a loss of production from multiple wells. The scope was to identify the path of communication between the inner and middle annulus of the subject well.

- Location India

- Well Type Gas-lift producer

-

Identified the source of sustained annulus pressure in a newly drilled well

-

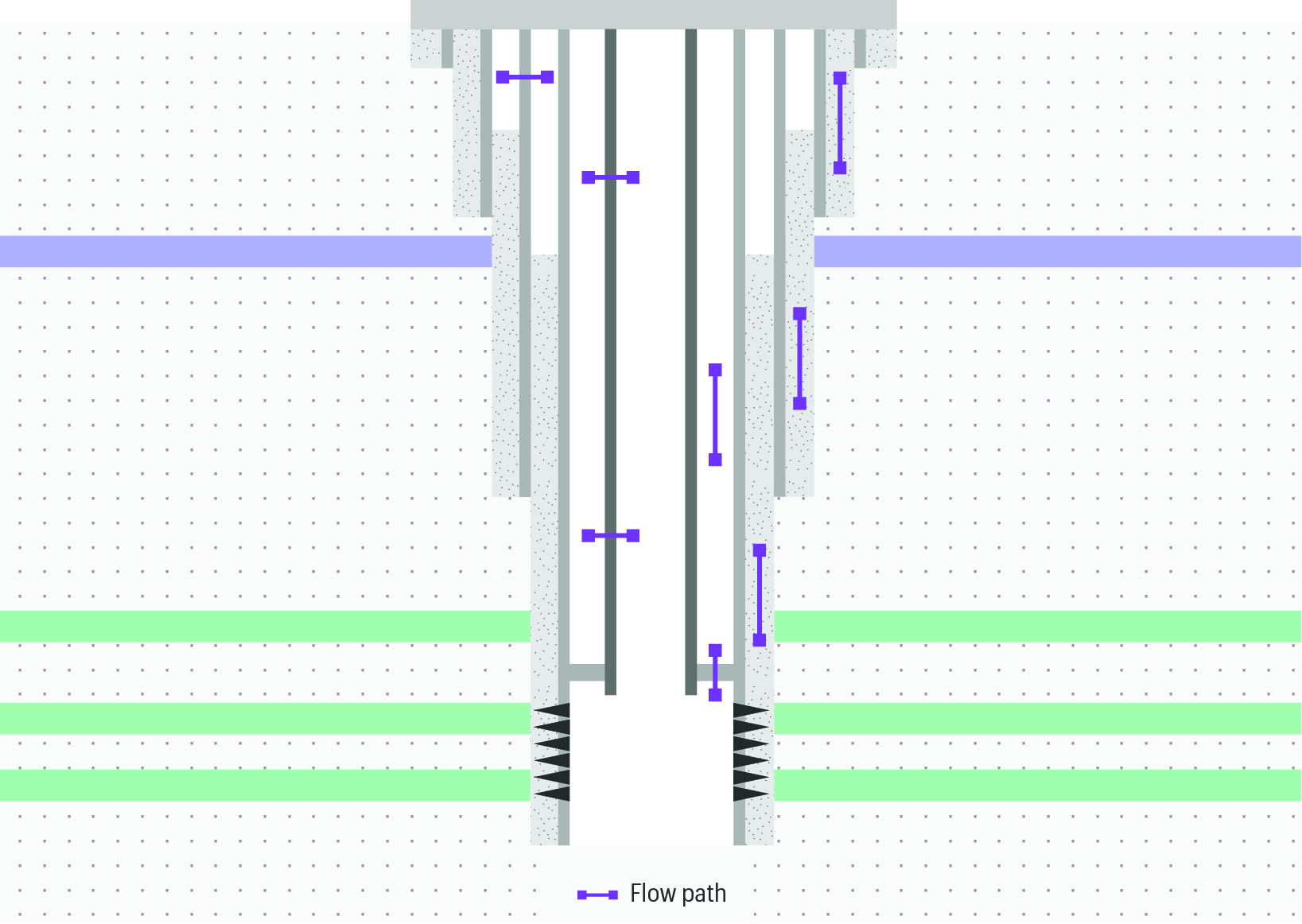

Identified seal failure which caused channeling to the surface behind the

9⅝” in casing

-

Enabled targeted remediation to restore well to safe and productive operations