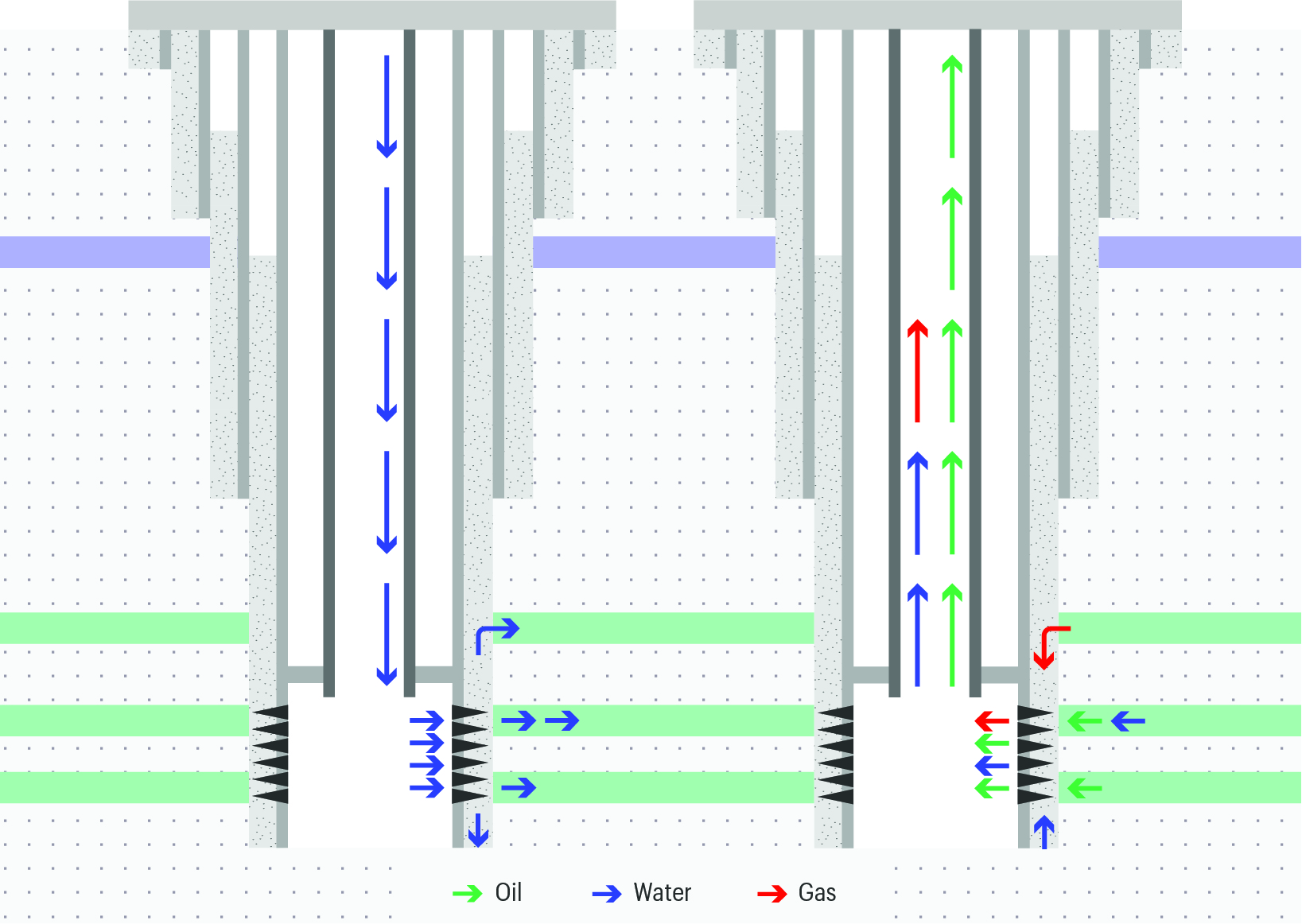

Petroleum and reservoir engineers determine that if water is injected at a particular pressure, then target reservoirs will receive a certain volume of water over time. If the predicted flow rate isn’t observed, then either something is wrong with the assumptions, or something is wrong with the well system—or both. Even worse, the predicted flow rate may be within range, but the water may not be reaching the target. The latter scenario is particularly insidious because it may be weeks, months or longer before an alarm is raised.

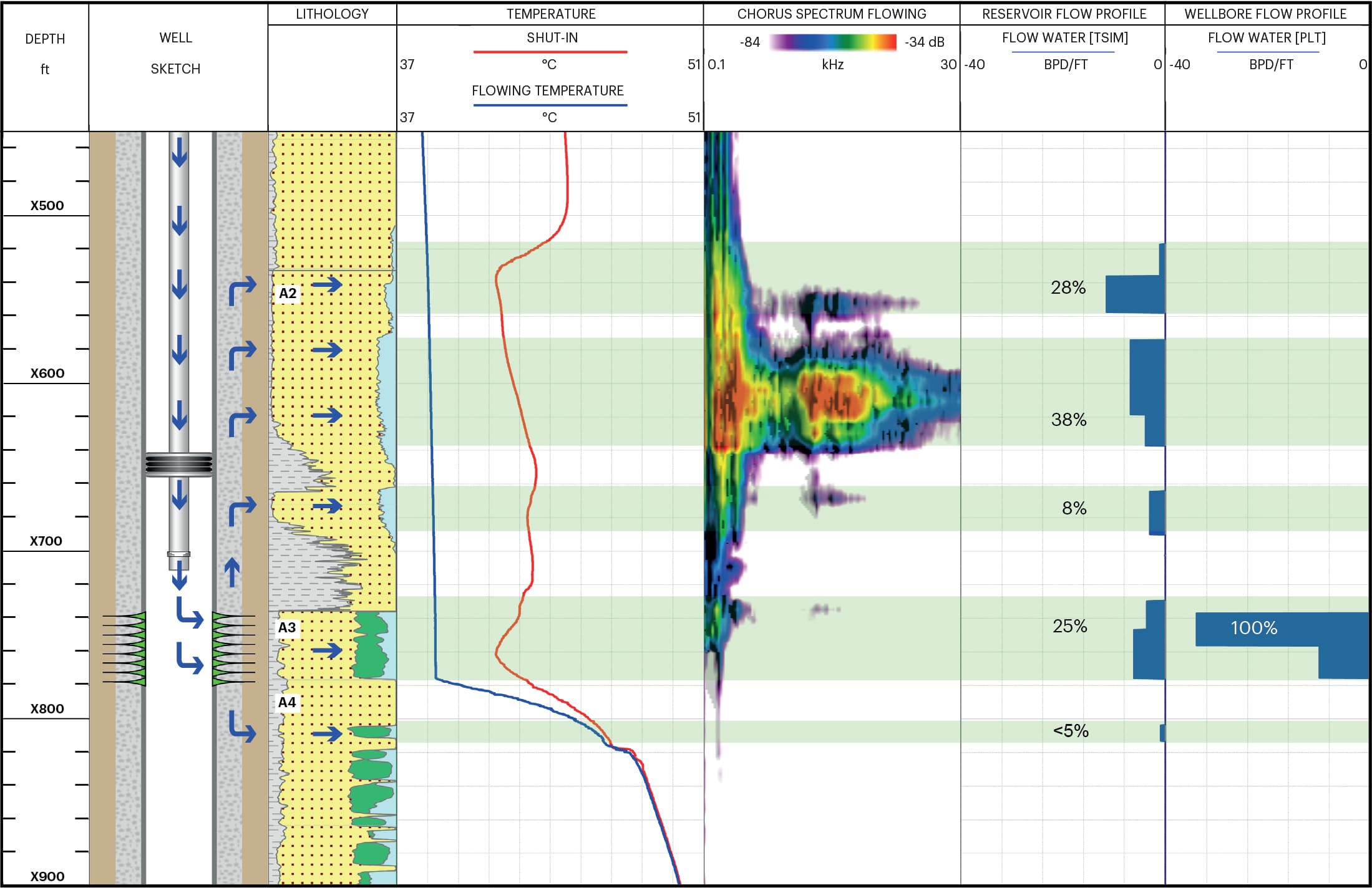

An operator was experiencing injection issues and needed to confirm whether the injected water was reaching the target reservoir.