In recent years, the Permian basin is been the most prolific shale play in the US. Production in this area increased to 3.8 million barrels by 2019, representing almost 70% of the whole US production growth from 2011 to 2019 according to International Energy Agency (IEA). The impressive aspect of this achievement is that the growth has not stopped. On the contrary, the Permian is expected to continue growing and is estimated to achieve up to 5.8 million barrels by the end of 2023.

Such impressive growth doesn’t come easy. Significant advances in drilling, completing and multi-stage fracturing will continue to drive production increases. But evaluating the performance of fracturing programmes and the wells they deliver is key to optimising resources and ensuring maximum return on investment. Conventional diagnostics [such as production logging tools or ‘PLT’s’] can’t provide all the insights required to ensure the operator is achieving the best returns. This article focuses on the challenges faced when assessing unconventional reservoirs in terms of production, and features a new diagnostic capability introduced by TGT to evaluate the flow performance of hydraulically fractured wells, stage-by-stage. The new diagnostic product is aptly called ‘Fracture Flow’.

Operators have been drilling aggressively and pushing the boundaries of hydraulic fracturing beyond conventional standards compared to other plays. The drilled length of lateral sections has been constantly boosted, adding more footage as well as more production stages. The ultimate objective is to penetrate deep into the target formation increasing the area of contact with the specific reservoir or formation making the well, its completion and the reservoir one dynamic production system.

Champions of this approach include a Houston-based operator that recently drilled such a well at the Wolfcamp. The completion included a lateral section of more than 17,900 ft running through the Spaberry formation. The completed well had a total measured depth exceeding 24,500 ft with a customised completion design and fracking treatment. The completion included more than 50-stages and sand was pumped along more than 2,200 ft of reservoir to increase the well productivity.

These extended laterals have been engineered to optimise production performance and leverage improvements in drilling, fracking treatments and completion designs. The operators have overcome the number of well construction challenges and have quickly moved up a steep learning curve.

Like the challenges encountered with well construction, the Permian basin faces its own challenges. Following such an extensive multistage hydraulic fracturing programme, the wells are brought onstream at high initial production rates. But most of these extended-lateral producers tend to decline dramatically over a very short period. To help combat this challenge, and many others, TGT has developed a number of application-specific diagnostic products using its ‘True Flow System’ to quantitively evaluate flow dynamics throughout the entire well system – from reservoir to the wellbore, and the dynamic interplay between the two.

When talking about a hydraulic fracturing job, we all know the importance of the programme design prior to execution. During this phase, sophisticated software is utilised to model and optimise the fracturing programme, taking into consideration multiple variables. These variables include formation properties, lithology, depth, mechanical stresses and other parameters that can affect the final outcome. Another important consideration is the formulation of the hydraulic fracturing fluid. This fluid is normally comprised of sand (or proppant), gels (foam or sleek-water) and additives that are pumped downhole following the job design to prop open the induced fractures and maximise the extension of the fracture in terms of length, height and aperture as well as the integrity of the fractured conduit itself, so hydrocarbons can flow unabated.

TGT’s diagnostic ‘Fracture Flow’ product is able to locate and evaluate fracture inflows and quantify inflow profiles in hydraulically fractured wells. The product is delivered by our analysts using the ‘True Flow System’, which combines several technology platforms – Chorus (acoustic), Cascade (thermal), Indigo (multisense) and Maxim (digital workspace), to acquire, interrogate and analyse the acoustic spectra and temperature changes generated by the hydrocarbons or any other fluid flowing from the reservoir through active fractures and into the completion. This diagnostic capability goes beyond conventional flow measurement techniques that generally stop sensing at the wellbore and are therefore unable to quantify flow within the reservoir itself.

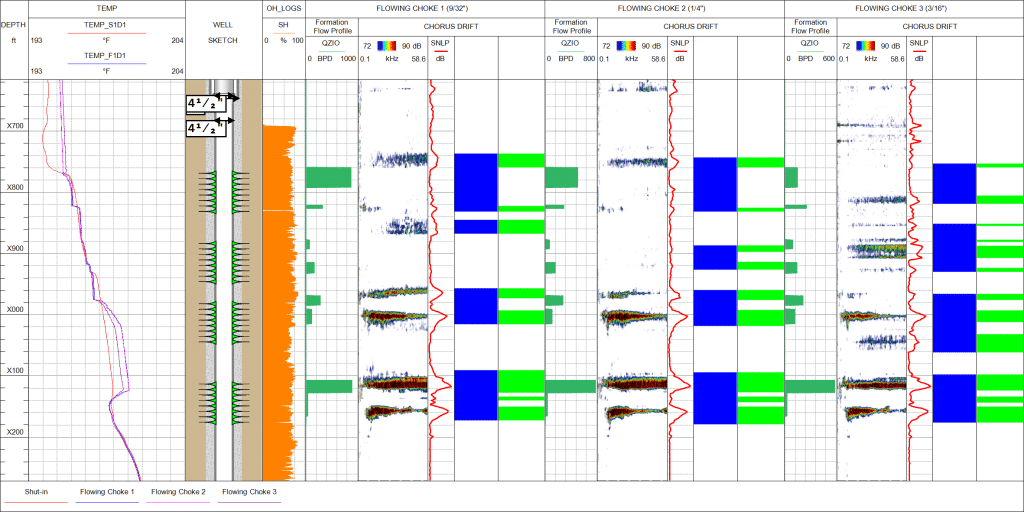

The Fracture Flow product extract shown in figure-1 represents the diagnosis of a hydraulically fractured oil producer with >80 degrees deviation. The reservoir has a gross thickness of approximately 1,200 ft and is fully cased.

To celebrate, TGT invited employees, customers, and business partners to an evening which relived the company’s scientific breakthroughs using acoustic, thermal and electromagnetic energy to reveal unique answers within and beyond the well bore.

Dr. Arthur Aslanyan, TGT’s Co-Founder commented, “It gave me great pride to attend the event and celebrate the company's 20th anniversary. We have come a long way since we first started the business. We are very excited about our future as the company continues to thrive”.

The event was attended by Saad Bargach, TGT Chairman and LimeRock Partners -private equity investors.

Hegazi continued, “Looking to our future, TGT is releasing several lines of new technologies and applications in coming months to further cement our position as pioneers of Through-Barrier Diagnostics. Our patent technology developments coupled with our unrivalled Geoscience organisation and global footprint, provide unique and reliable diagnostic services to our customers. This has been key in maintaining our fast growth trend and industry reputation. I am confident this foundation along with our excellent teams, will continue to fuel our growth for many years to come.

The operator’s objectives in this case were to evaluate the post-fracture performance of three zones, and in particular:

- Compare the effectiveness of fractured stages by assessing the production contribution from each fractured interval

- Identify crossflow or behind-casing communication

- Increase production efficiency by identifying the optimum production choke for this well system.

The results revealed by the Fracture Flow analysis clearly revealed that the fractured intervals (figure-1 – blue coding) were not contributing fully to production in their entirety. Furthermore, it identified exactly the active zones and where the main production was coming from (figure-1 green coding). Fracture Flow revealed that only 62%, 59% and 56% of each zone was actually producing at the outset.

The Fracture Flow analysis also indicated that there were no crossflows among the three zones which was another key finding from an integrity perspective.

Thirdly, the Fracture Flow diagnostic programme helped to determine the optimal choke size required to ensure that the fractured zones were contributing at maximum rate.

TGT work in close collaboration with operators using Fracture Flow to help them reach their frac evaluation objectives; locate effective fracture inflows; quantify inflow profiles; and assess the effectiveness of fracture programmes, helping to optimise future programmes and maximise return on investment.

TGT is an international diagnostics company that specialises in ‘through-barrier diagnostics’ for the oilfield. Our Houston-based operation provides unique ‘True Flow’ and ‘True Integrity’ diagnostics to operators throughout the United States, including the Permian. We are also working actively in deep water Gulf of Mexico, Latin America and other major basins around the globe. Our diagnostics help operators make better decisions so they can manage wells safely, productively and profitably. tgtdiagnostics.com