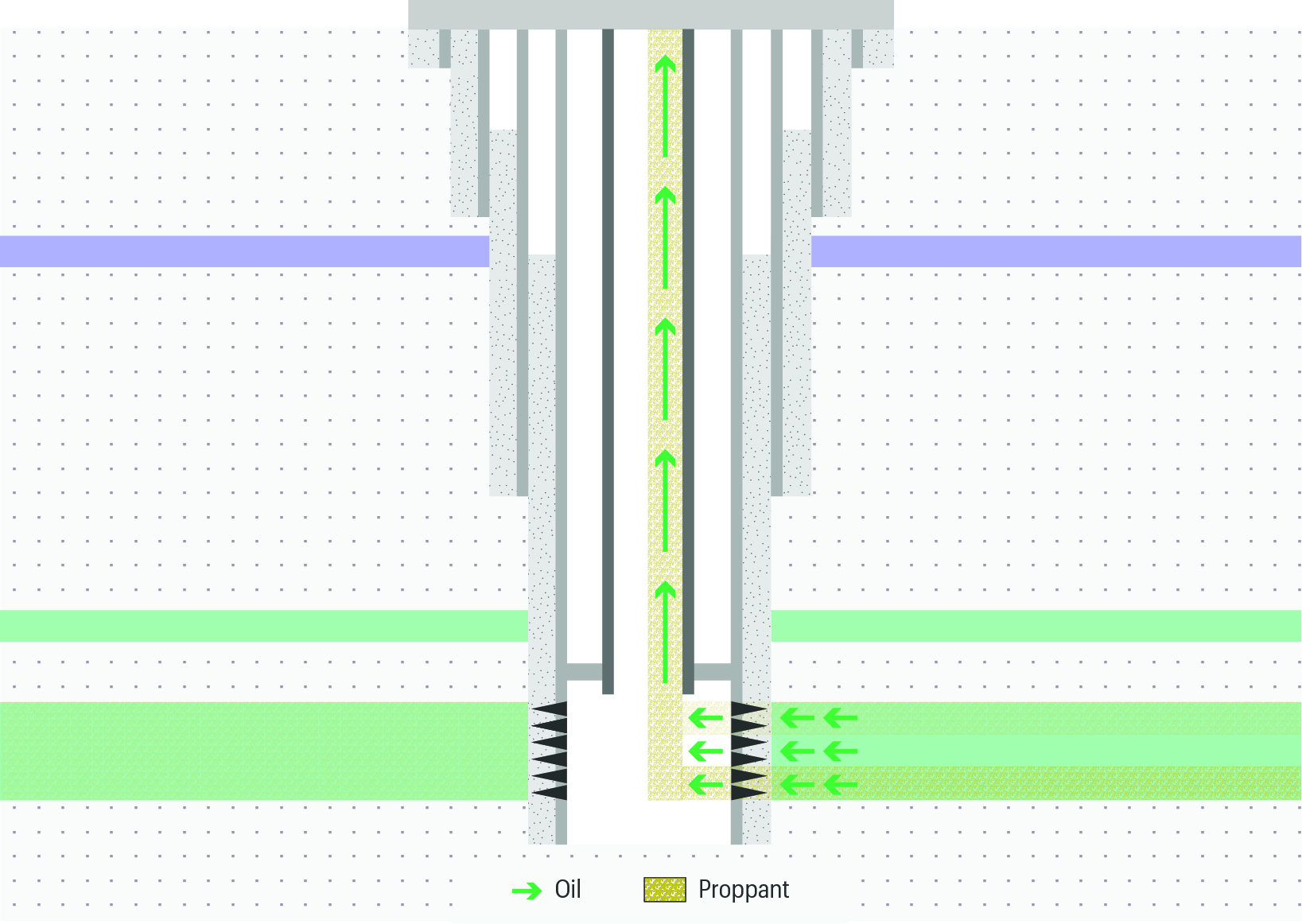

Solid particles can be transported from the reservoir into the wellbore when an oil or gas well is flowing. These particles may be natural solids such as sand grains or proppants that were injected into the reservoir during hydraulic fracturing. Identifying the sources of solids entering a well is a vital first step to controlling the problem.

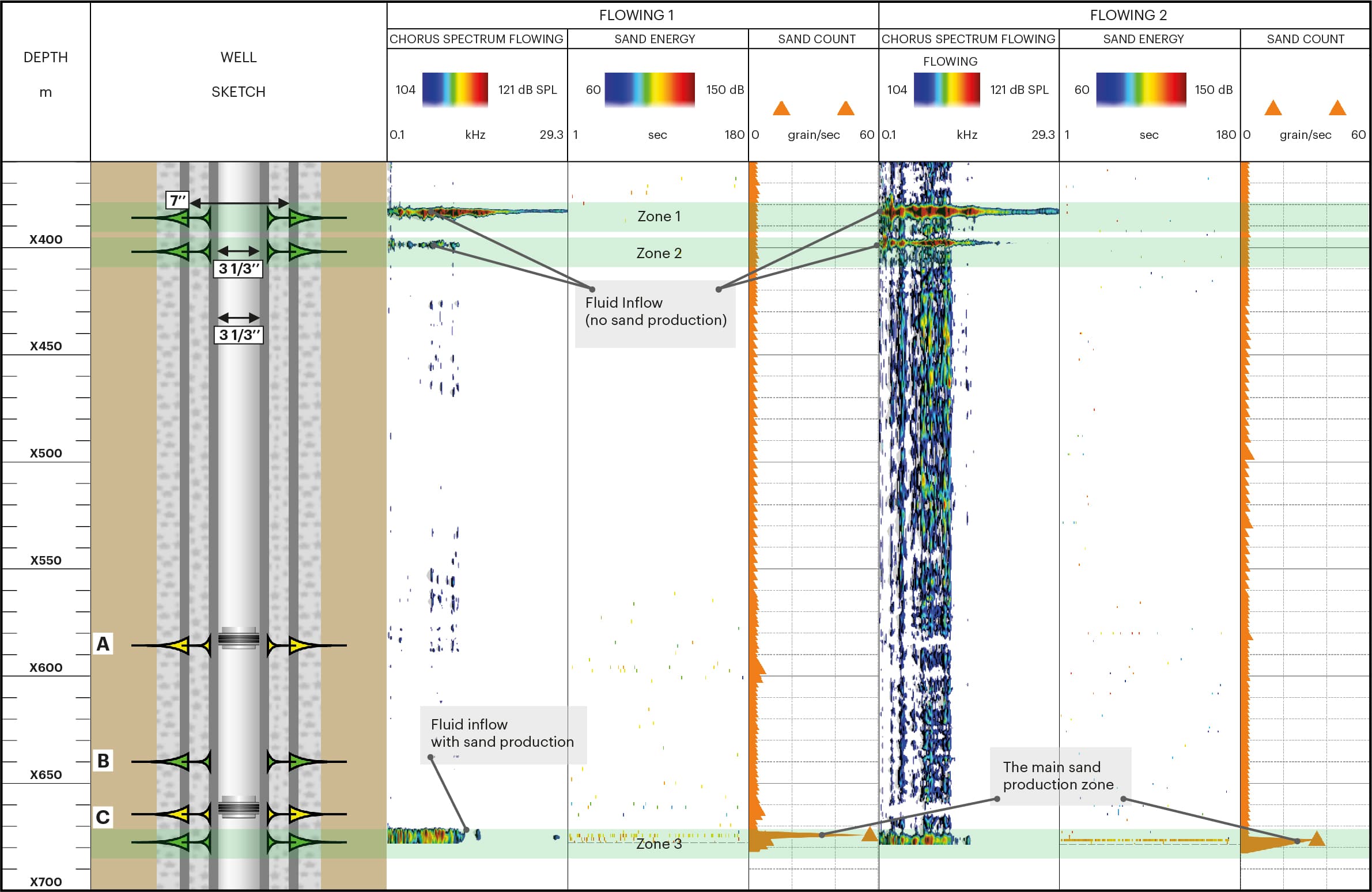

This well is a deviated producer in a giant natural gas field in the South China Sea. Drilled and put on production during 2010, the well was found to be producing sand at about 120 cm3/hr in 2017, which resulted in the well being shut in. The operator wanted to identify and eliminate the sources of sand and resume production.