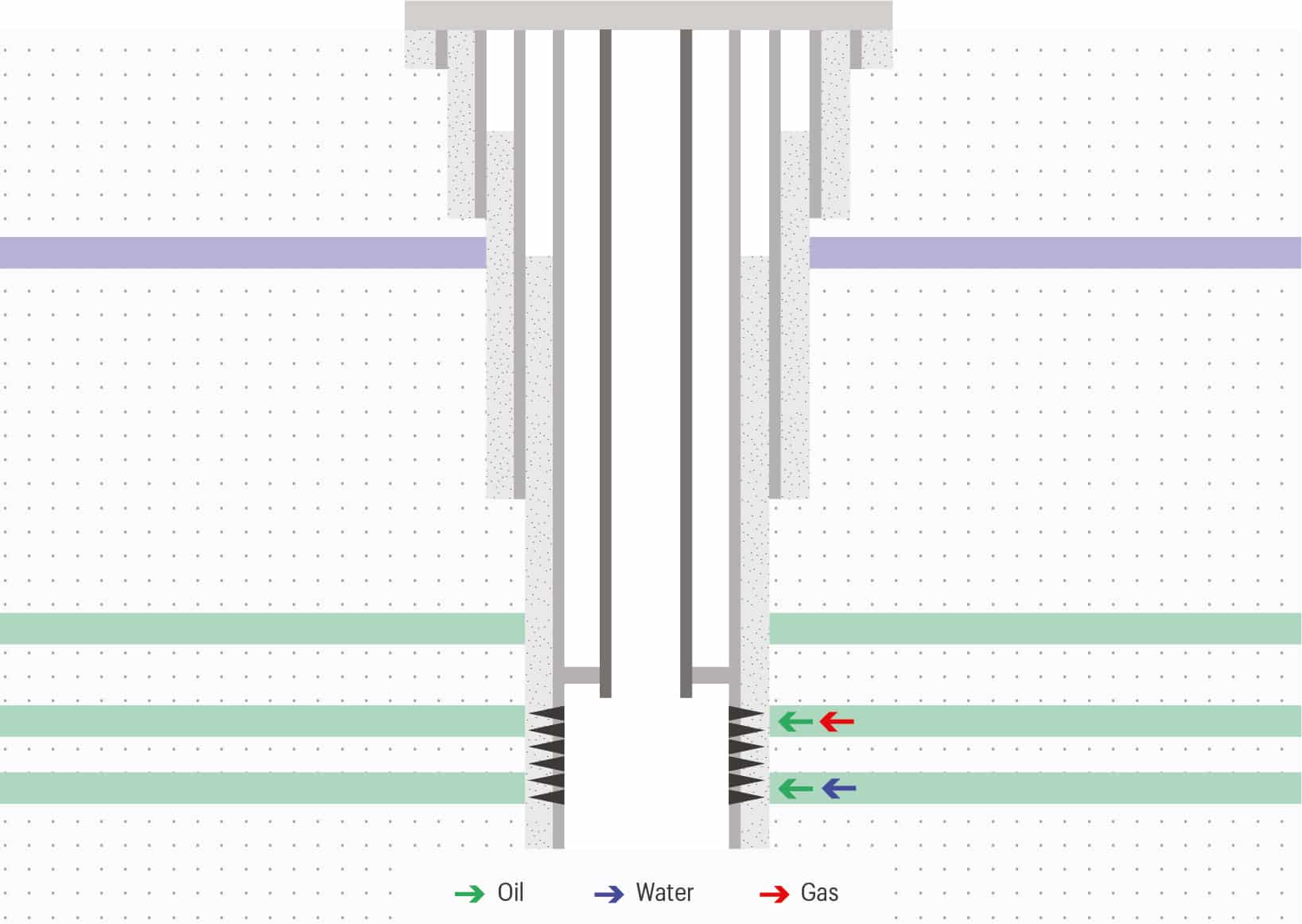

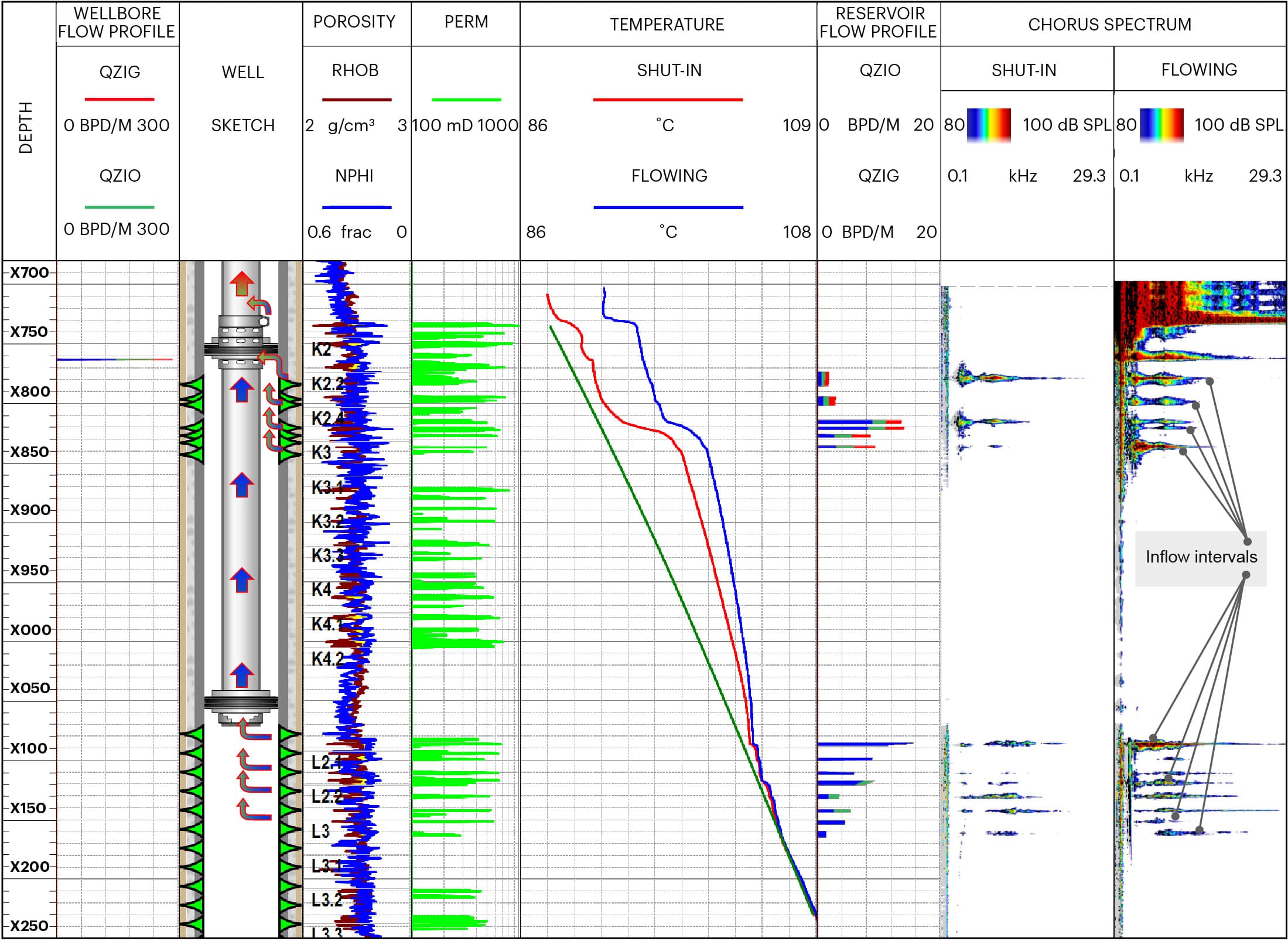

Waterflooding involves injecting water into a reservoir, usually to increase pressure and thus stimulate production. However, when this action is being performed in a multi-layer reservoir it requires constant monitoring to identify the potential for water breakthroughs and target intervals not flowing, that may affect fluid production. The operator’s main goal was to gain a quantitative assessment of the flow contributions from each layer in the producer well, particularly in the undersaturated reservoir areas which hold free gas behind the tubing and casing.

- Location Thailand

- Well Type Oil producer

- Reference SPE-191011

-

Identified active layers using Chorus acoustic platform

-

Calculated flow contributions in the producer

-

Provided information for potential zonal isolation or recompletion programs that would enable the operator to optimise waterflood performance