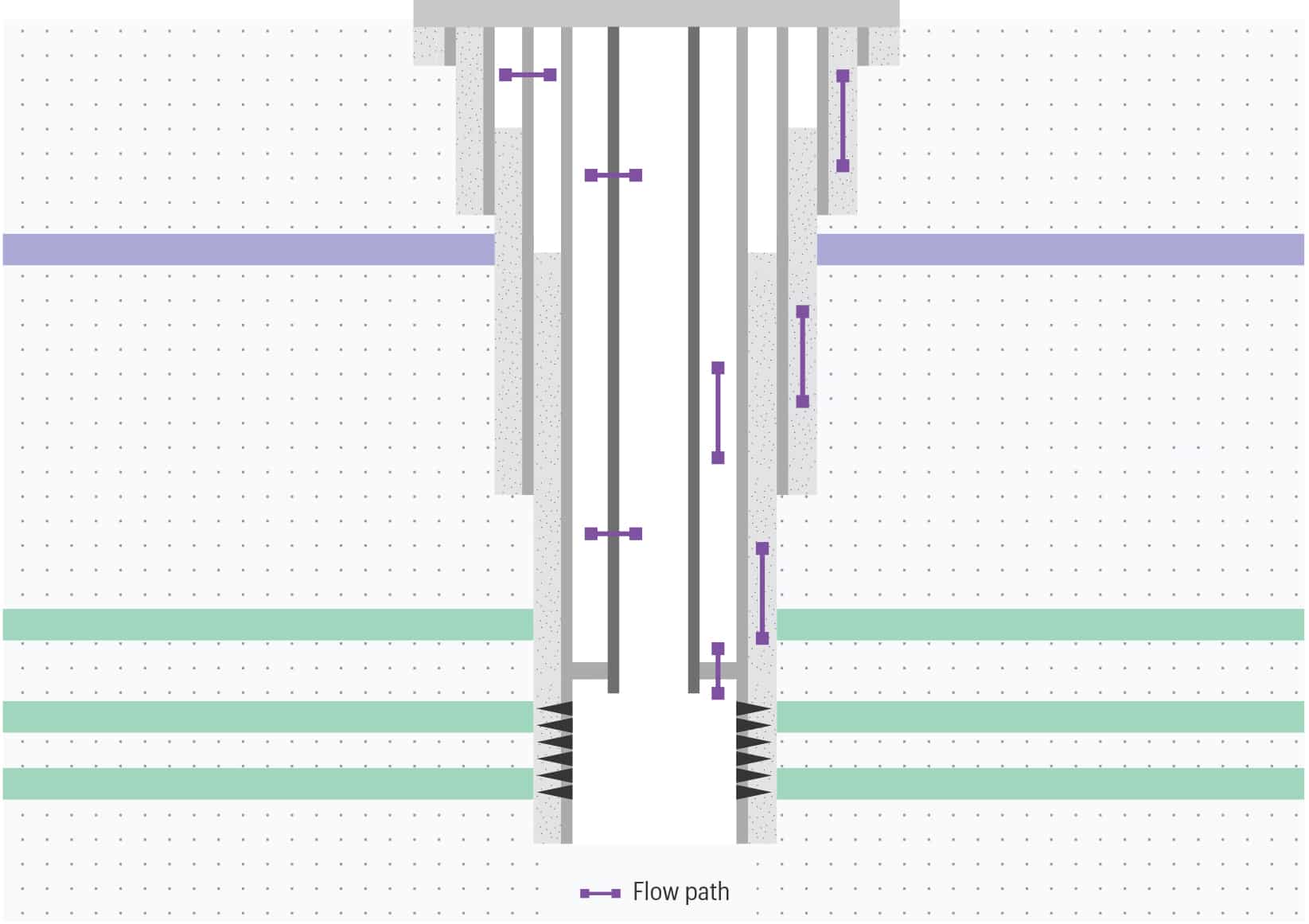

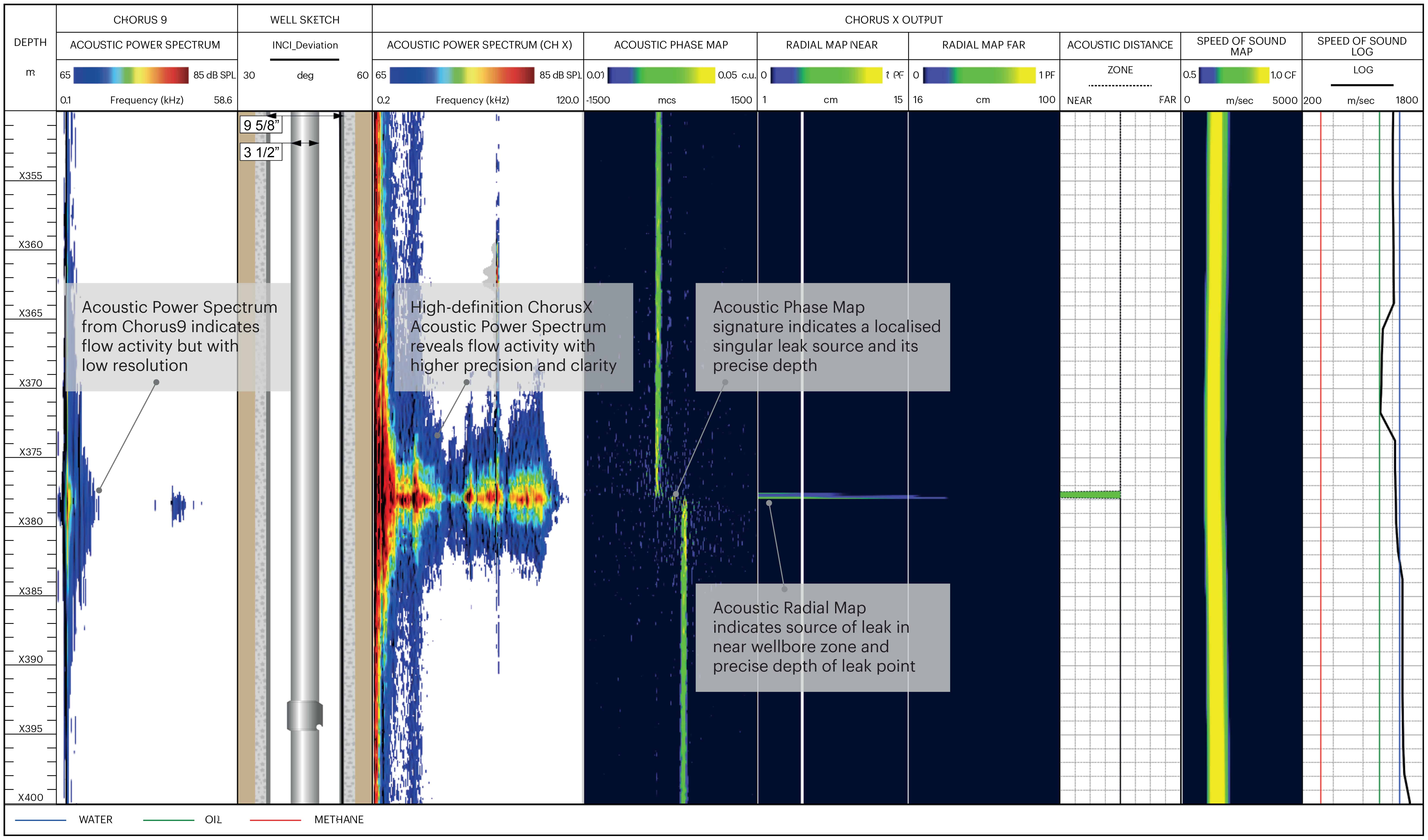

Leaks observed in an active well in the Netherlands forced the operator to suspend the well. An initial examination indicated that the integrity breach could be located in the tubing, casing or any of the completion elements within or beyond the A-annulus envelope. A pressure test confirmed that the leak rate was small, just 0.25 bar per day, but this was sufficient to pose a health, safety and environmental risk and trigger the suspension of the well.

Leaks in the well system are a serious issue, and well integrity engineers want to understand precisely how and where the leaks originate so they can be repaired. The combination of many potential leak points spanning the length of the completion coupled with a small leak rate made this a challenge to investigate. The operator needed diagnostics technology that had a large radial reach and was both sensitive and accurate enough to scan for leak points and help steer a repair programme.