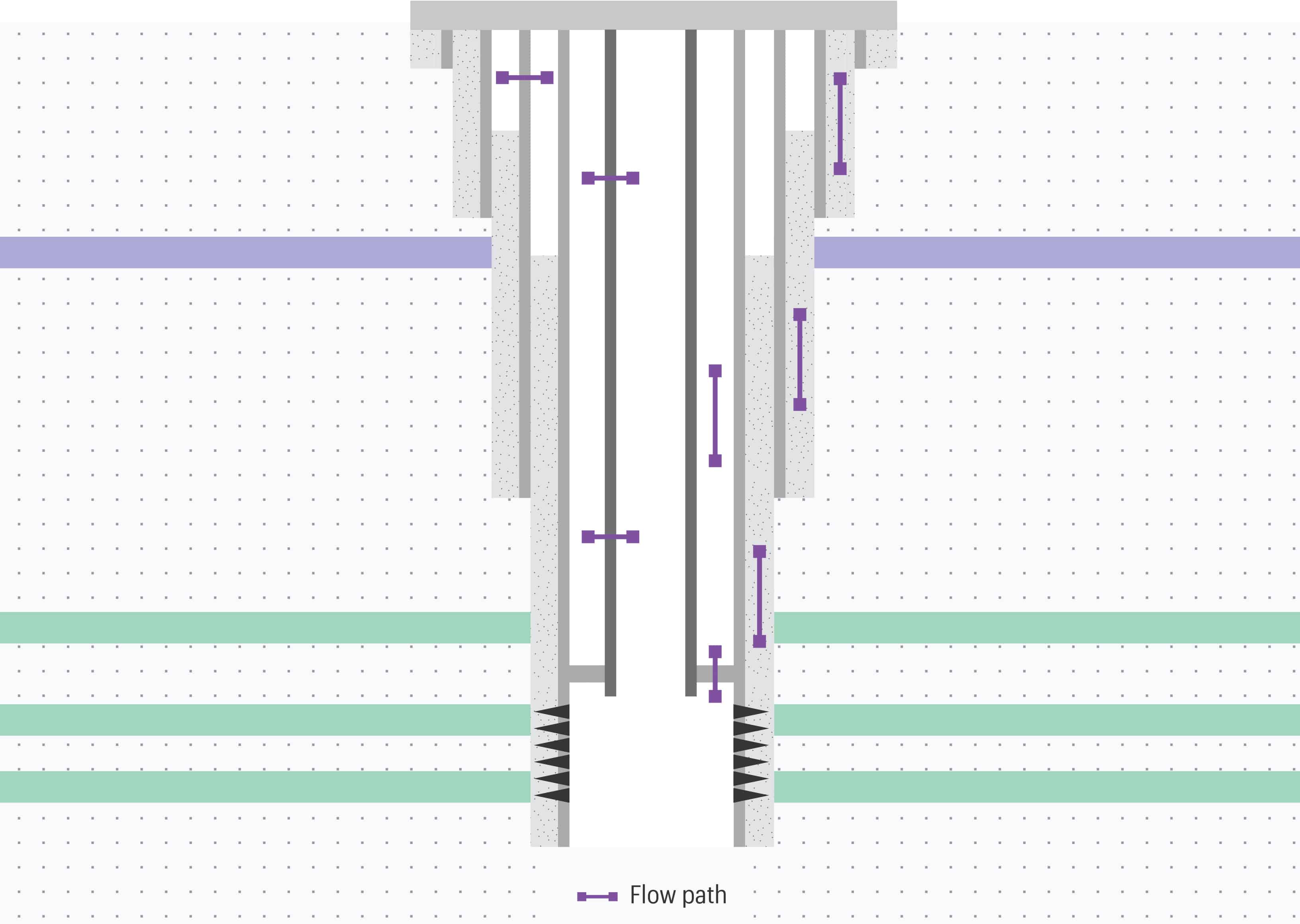

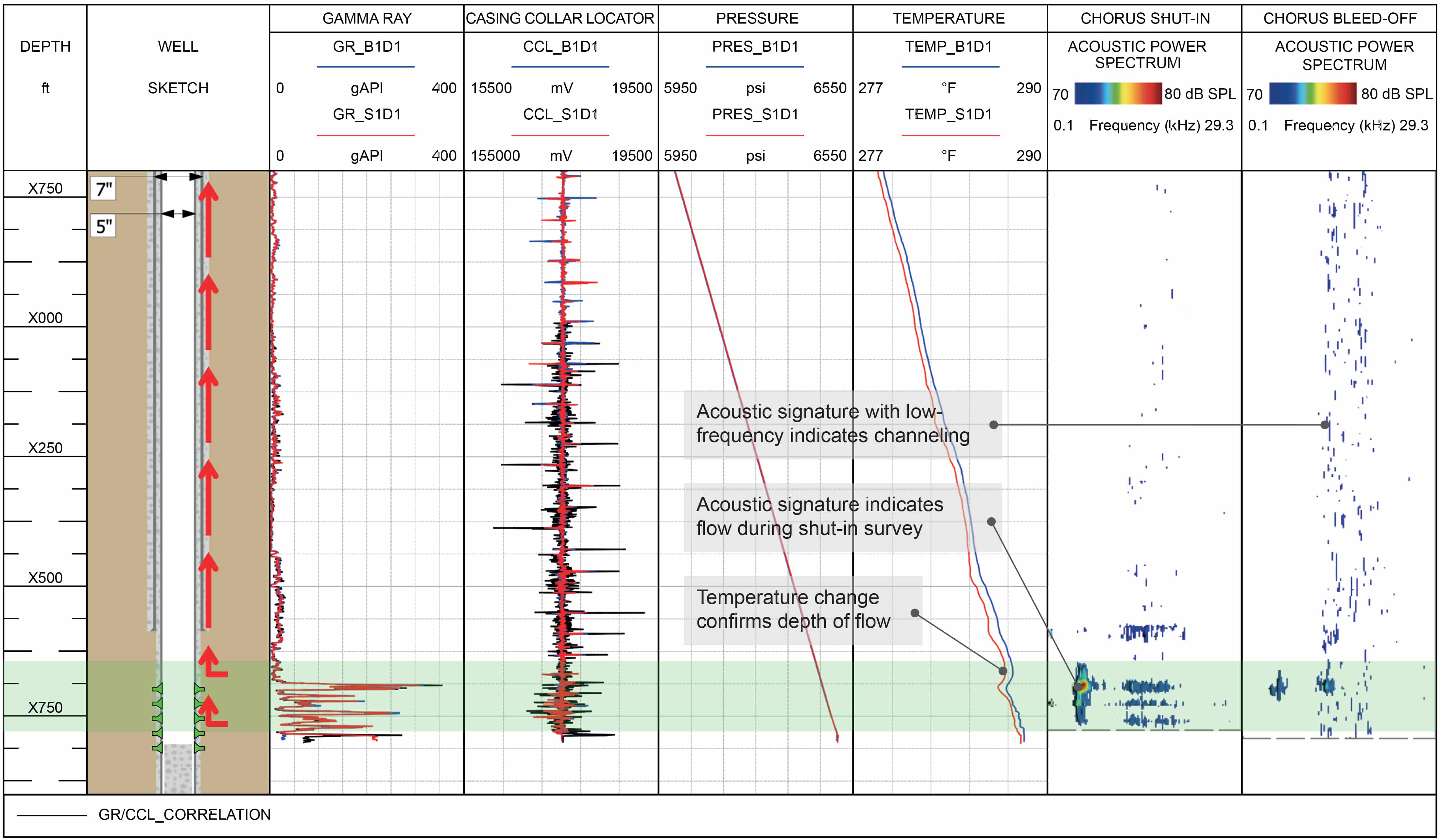

The operator of this North African oil producer was planning a workover to replace a leaking production string. As part of the work process, the client wanted to locate and eliminate the sustained annulus pressure (SAP) in the B-annulus between the 7-in. and 9⅝-in. casings. SAP indicates an underlying integrity problem. In this case, pressure was building to approximately 100 psi over a period of 10 hours, indicating a progressive annular leak that could become worse over time.

Accessing the B-annulus and making repairs, such as cement squeeze operations, is much easier when the tubing has been removed. The main challenge was accurately identifying the leak source and flow path associated with the SAP. Conventional temperature measurements can indicate flow behind casing but they lack precision, especially when the source is in an outer annulus and the sensor is located inside the tubing. Accurately determining the source of the SAP would be the first step to planning and implementing a successful remediation.