Multistage fracturing is a highly effective development strategy for ultralow- to low-permeability reservoirs. However, in uncemented completions with fracturing sleeves and packers, it can be challenging to identify fracture initiation points and confirm the number of fractures initiated in each treatment.

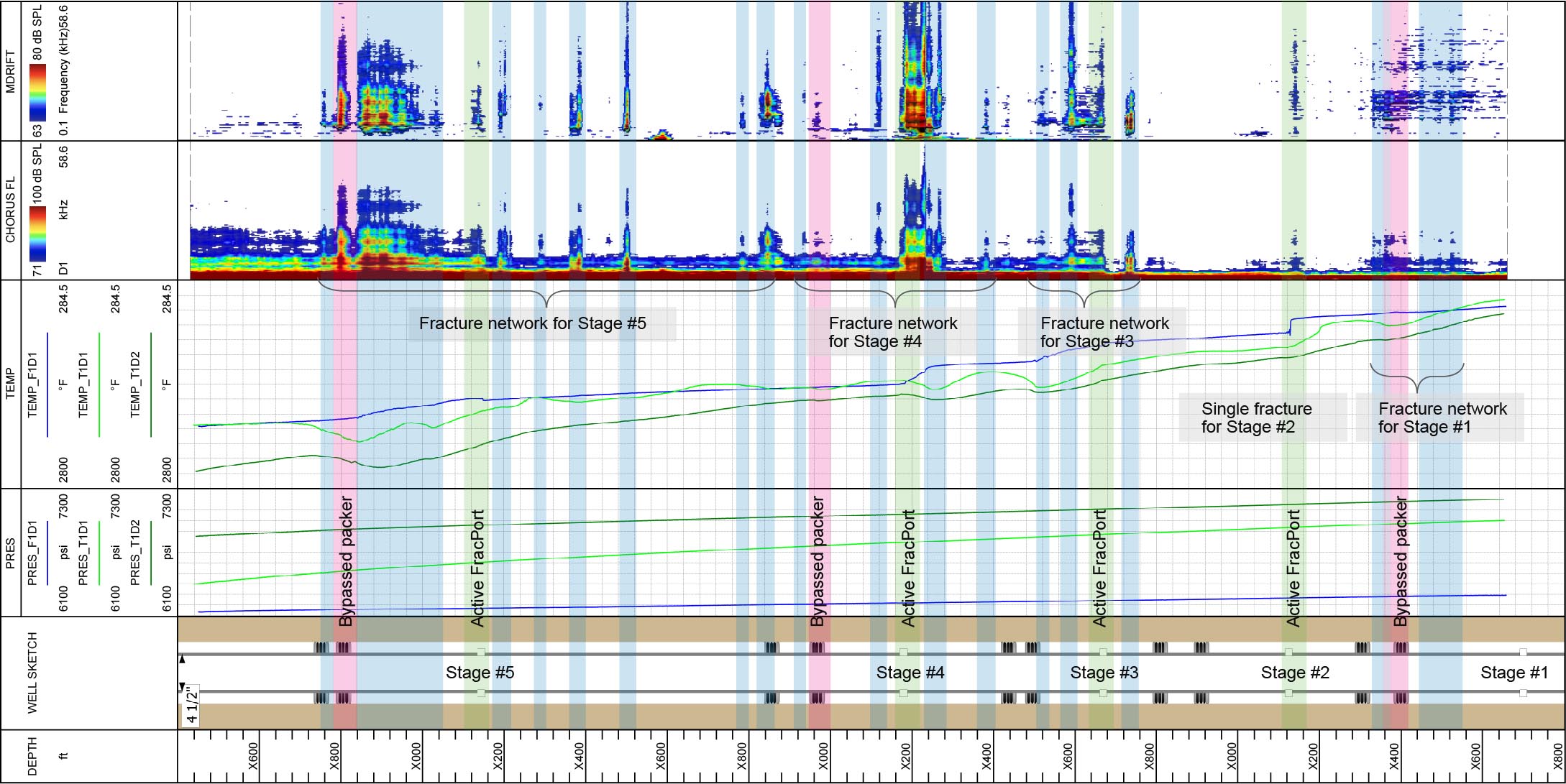

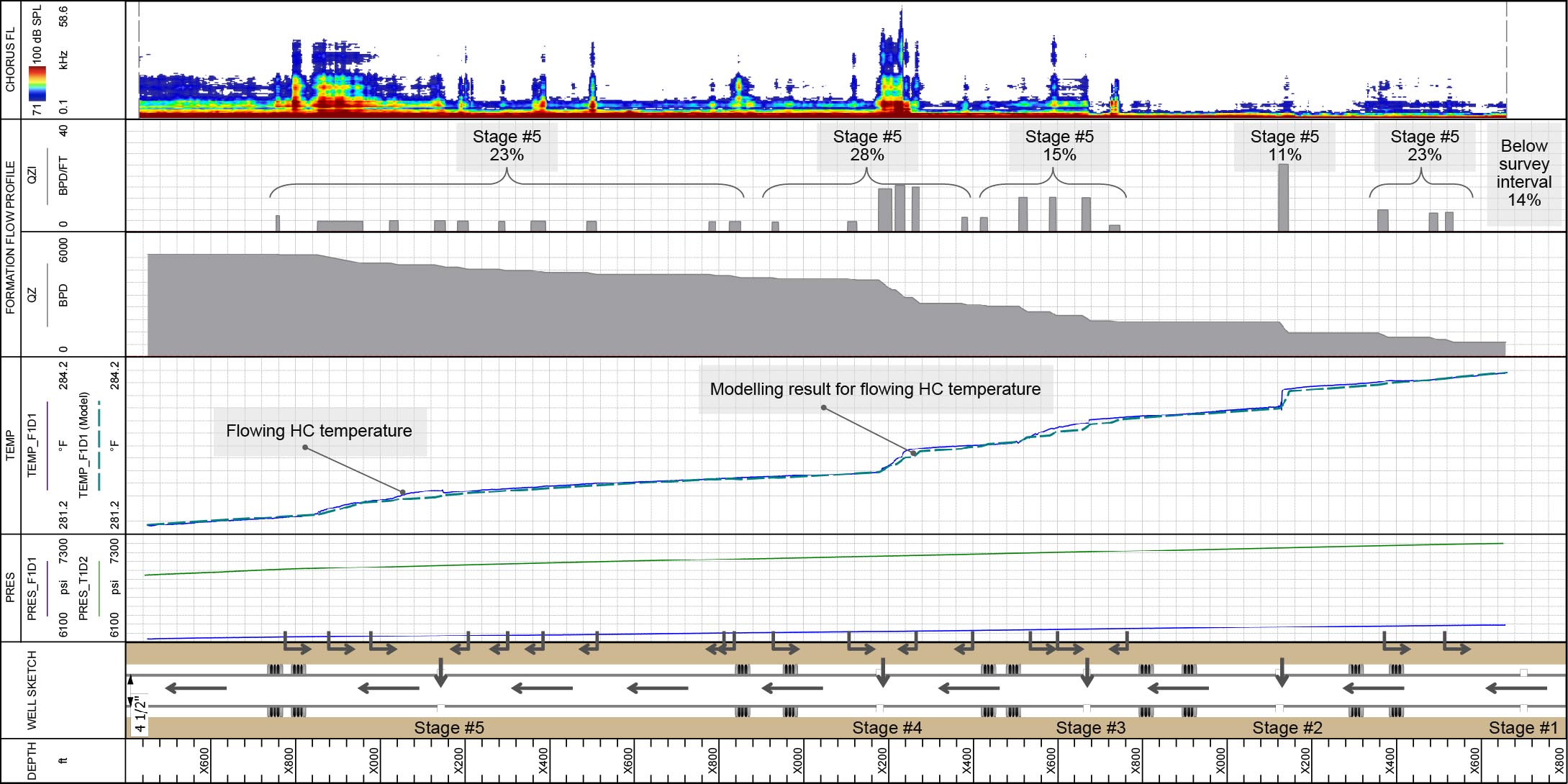

A lateral wellbore in a horizontal gas producer was completed with more than 3,000 ft of open hole (OH) section across five fracturing stages in a high-temperature and high-pressure tight-gas interval. This well presented several key challenges.

- With OH intervals ranging from 200 to almost 1,000 ft, the operator could not be sure how many fractures had been created or where precisely these fractures were located.

- The initial stage plan was not sufficient to guide packer placement. Placement had to be decided in conjunction with the caliper log and gauged hole analysis.

- Interstage communication owing to packer bypass or ball failure is a common problem in completions of this kind. This can be caused by higher differential pressure being exerted on the packers during fracturing.