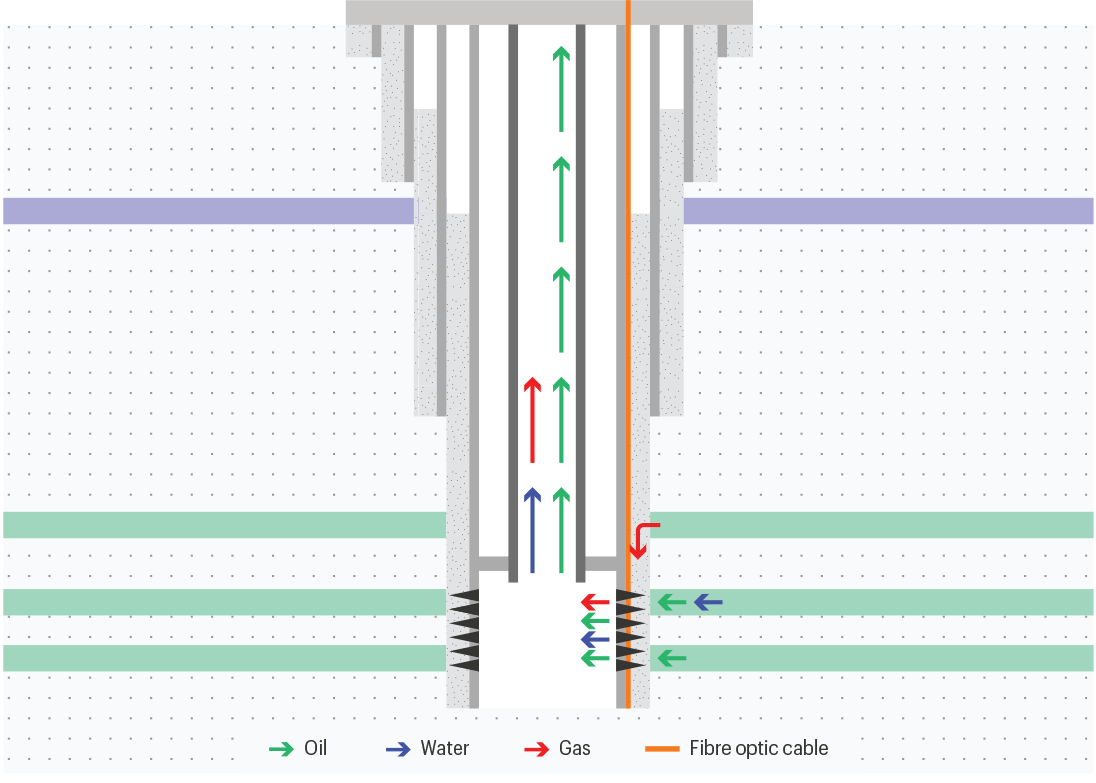

In commingled injection schemes, it is essential to determine the distribution of injection rates among the different layers. This is traditionally achieved using conventional production logging surveys. Cost is also an issue, as operators have to cover the costs of the survey and the mobilisation of crew and equipment to the wellsite. In addition, conventional surveys have a small associated health, safety and environment risk because production logging tools have to be run inside the wellbore during active injection. Consequently, the industry is always seeking accurate and cost-effective injection profiling methods that reduce health, safety and environmental risks and utilise existing resources.

- Location Oman

- Customer Petroleum Development Oman

- Field Thuleilat

- Well type Water injector

- Reference SPE Norway article

-

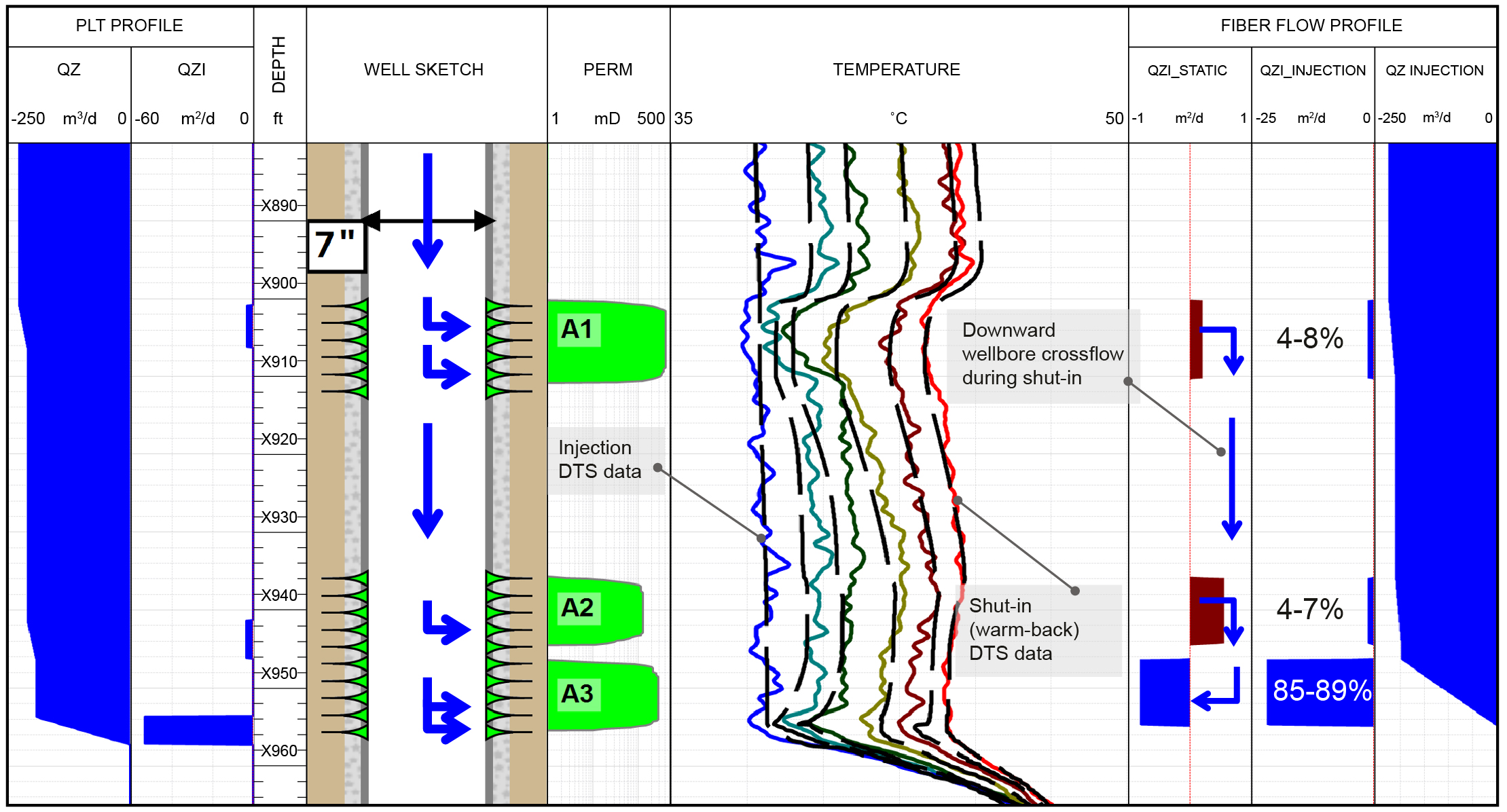

Validated Fibre Flow as an accurate and more efficient alternative to conventional production logging that maximises use of existing fibre systems

-

Revealed and quantified a downward crossflow during shut-in

-

Reduced survey costs and eliminated the health, safety and environmental risks associated with conventional production logging methods