Article featured in Harts E&P

The last few decades have brought impressive advances in ‘production logging’ technology, especially in the context of new sensor designs and diagnosing complex flow downhole. Fibre optics are also playing an increasing role in production surveillance. However, the fundamental technique of using wellbore-confined production logging tools (PLT’s) to infer total well and reservoir flow performance still dominates the industry.

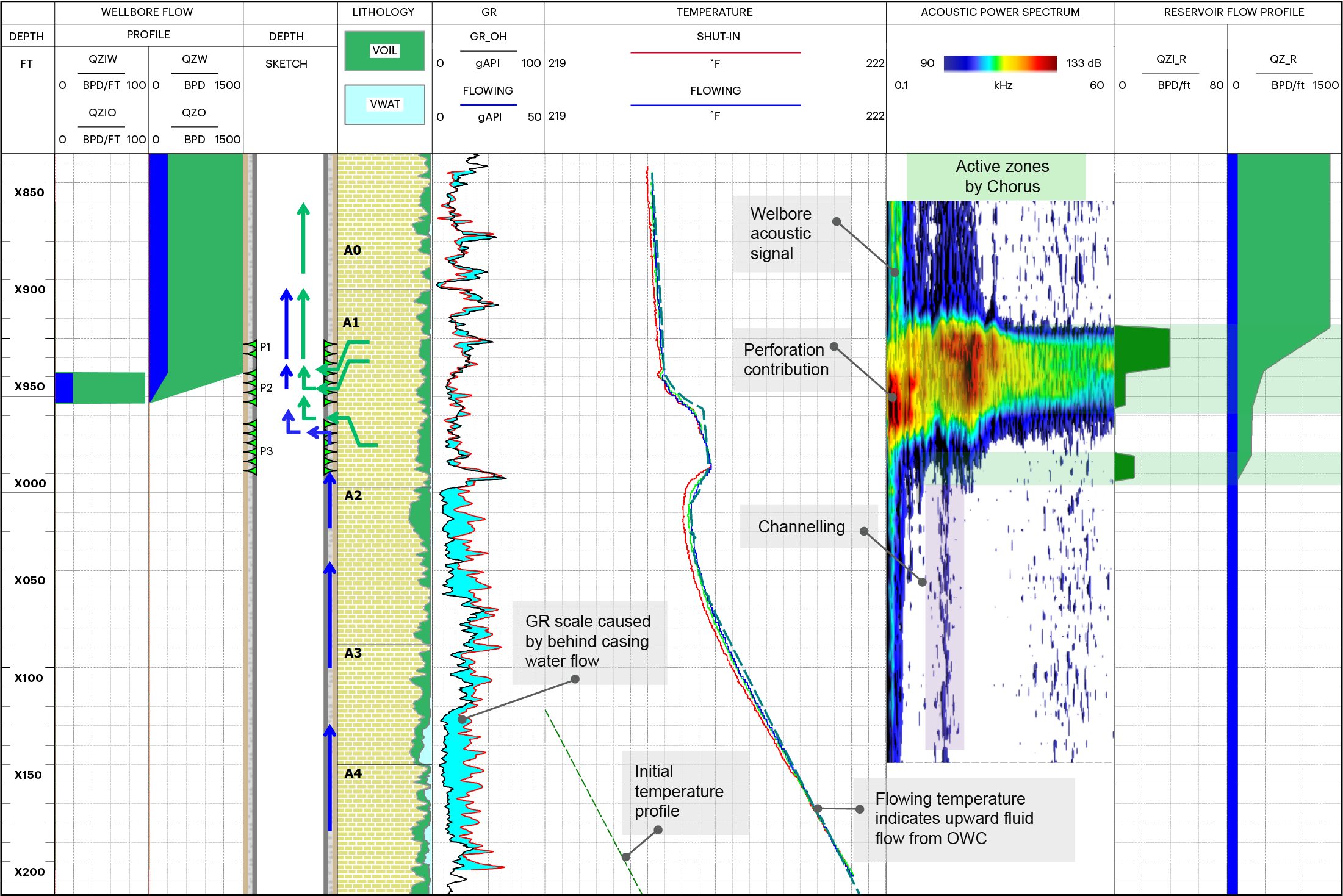

Basically, PLT measurements are used to monitor fluid properties and flow dynamics in the wellbore and importantly, to determine production and injection ‘flow profiles’ where fluids enter or exit the wellbore, such as via perforations or inflow control devices. These measured and calculated flow profiles are used to assess the production and injection performance of the entire well system.

However, the validity and accuracy of this approach depends on many factors, and chief amongst them is the ‘integrity of communication’ between the wellbore and reservoir formations at the entry/exit points. Analysts and operators using PLT’s must assume that fluids entering or exiting the wellbore are flowing radially from or to the formations directly behind the entry/exit points. And unfortunately, this is often not the case. Flowpaths can exist through annular cement channels, formation packers or natural fissures, and fluid will always find the path of least resistance. From a compliance, environmental and performance perspective, these unwanted flowpaths are bad news. Decisions made assuming wellbore flow correlates directly to target reservoir flow can lead to complex reservoir and field management issues, and compromised asset performance. From a diagnostics perspective, it’s clear that analysts and operators can’t rely on PLT’s alone to diagnose and manage well system performance – a more powerful diagnostic approach is needed.