In cyclic steam stimulation and steam-assisted gravity drainage, the reservoir fluids are heated through steam flooding to increase the mobility of heavy oils.

The steam is transported to the reservoir through the producing well. Consequently, the well’s casing metals and cement sheath are exposed to temperatures up to 300°C.

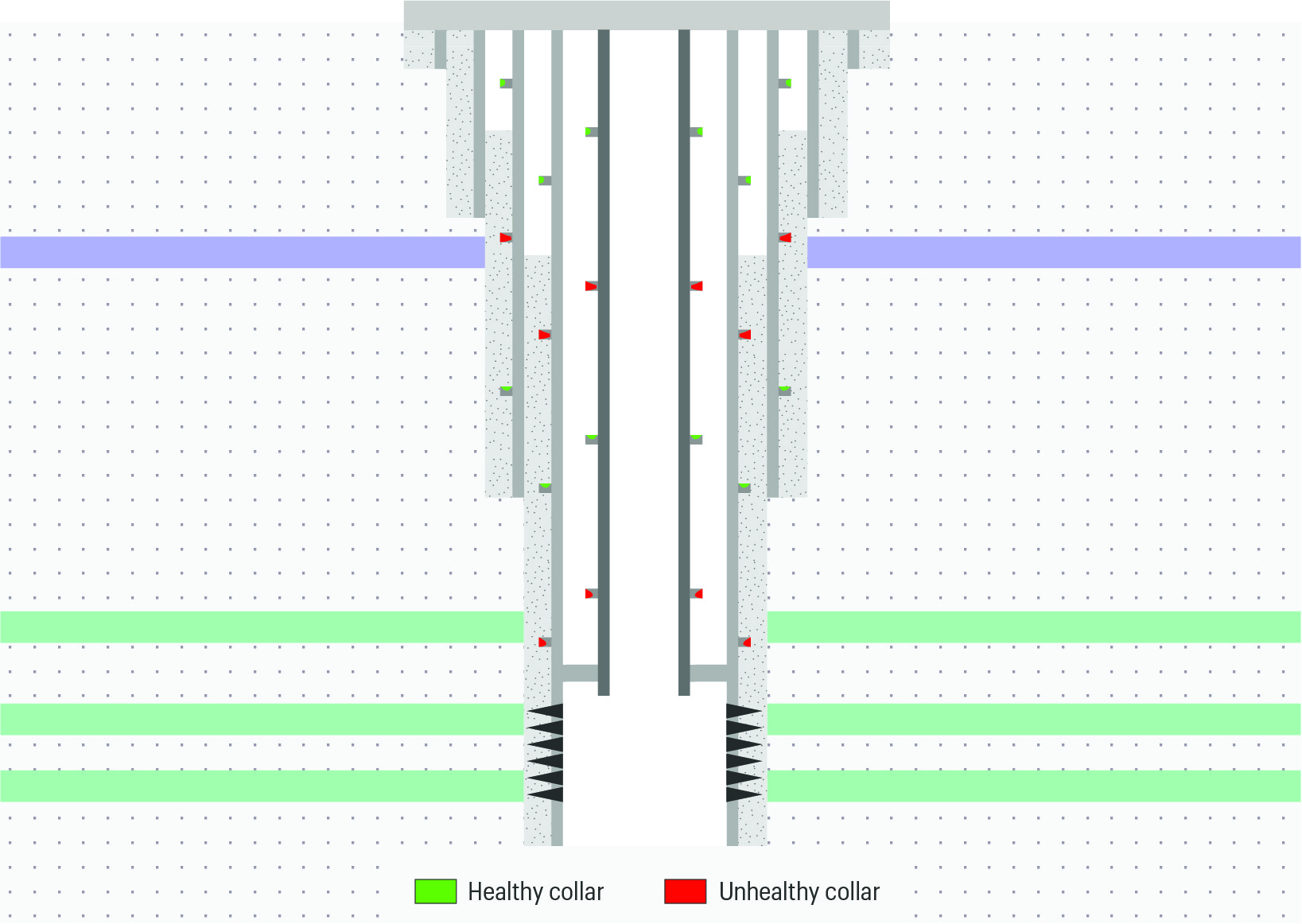

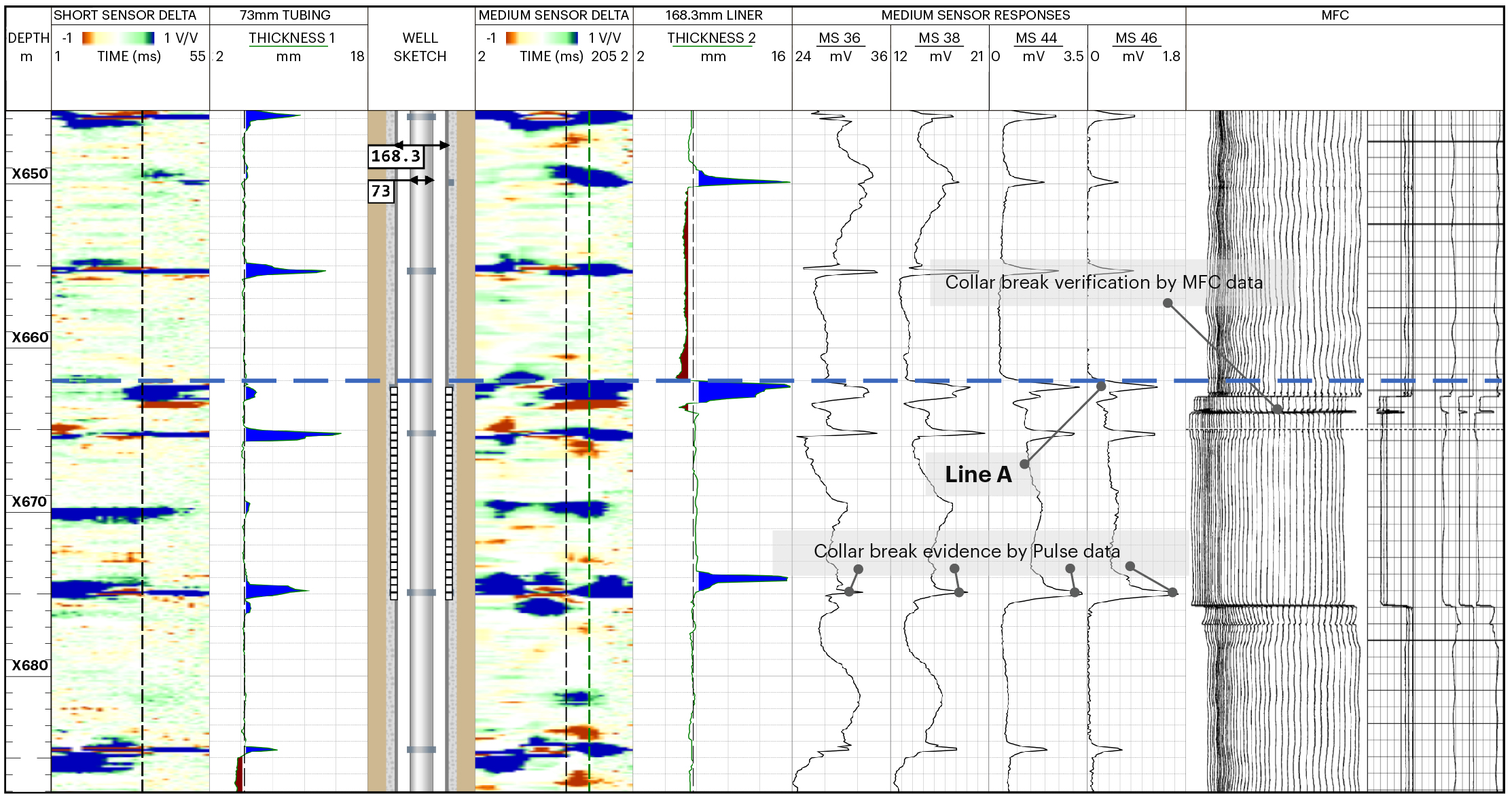

A common problem in cyclic steam injection operations is the failure of casing connections due to induced coaxial stress, which requires quick and reliable verification. To optimise cost operators need to identify issues downhole, such as casing collar breaks, without retrieving/pulling the tubing. In this case, an operator in northeastern Alberta, Canada, wanted to check the integrity of a producing well with 73 mm tubing inside a 168.3 mm slotted liner.