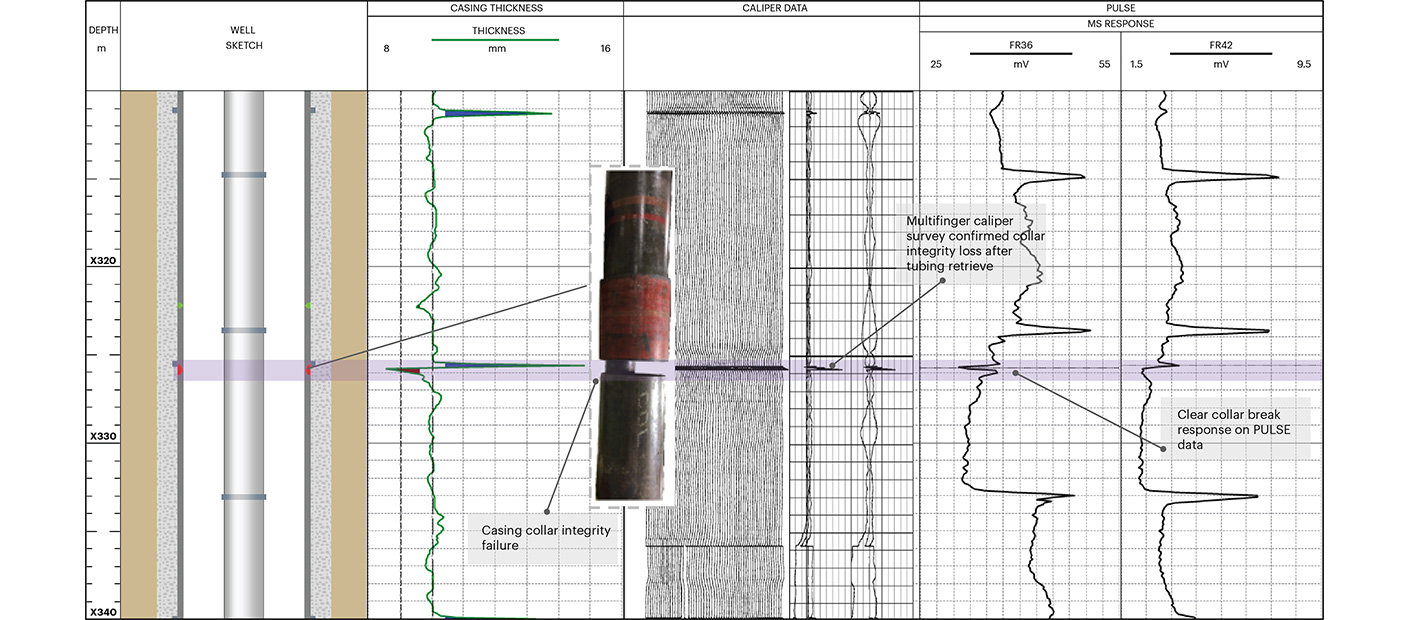

Casing connections are particularly prone to corrosion or damage. This can be due to fluid entry and galvanic forces between the threads accelerating decay or due to thermal expansion causing mechanical stress across the well construction. Regular monitoring is important to maintain integrity.

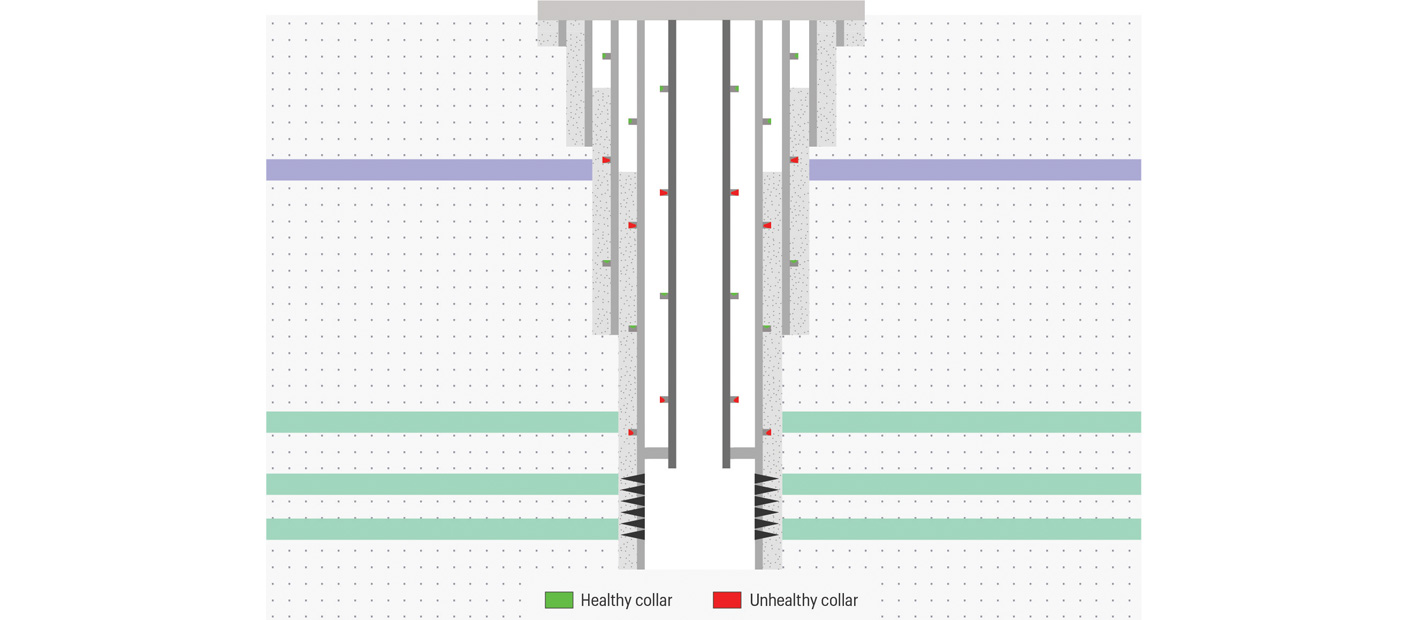

Collars Tube Integrity provides a collar-by-collar assessment of casing connections from a single through-tubing deployment.

Powered by our True Integrity system using the Pulse (electromagnetic) platform, Collars Tube Integrity delivers clear visibility of collar connection status through multiple barriers.

Collars Tube Integrity, if used routinely, can support your ongoing integrity management programme, or in a targeted fashion to investigate a specific integrity breach.

Our ability to assess up to four concentric tubulars simultaneously means that most of the collars can be evaluated in a single deployment, without pulling the tubing.