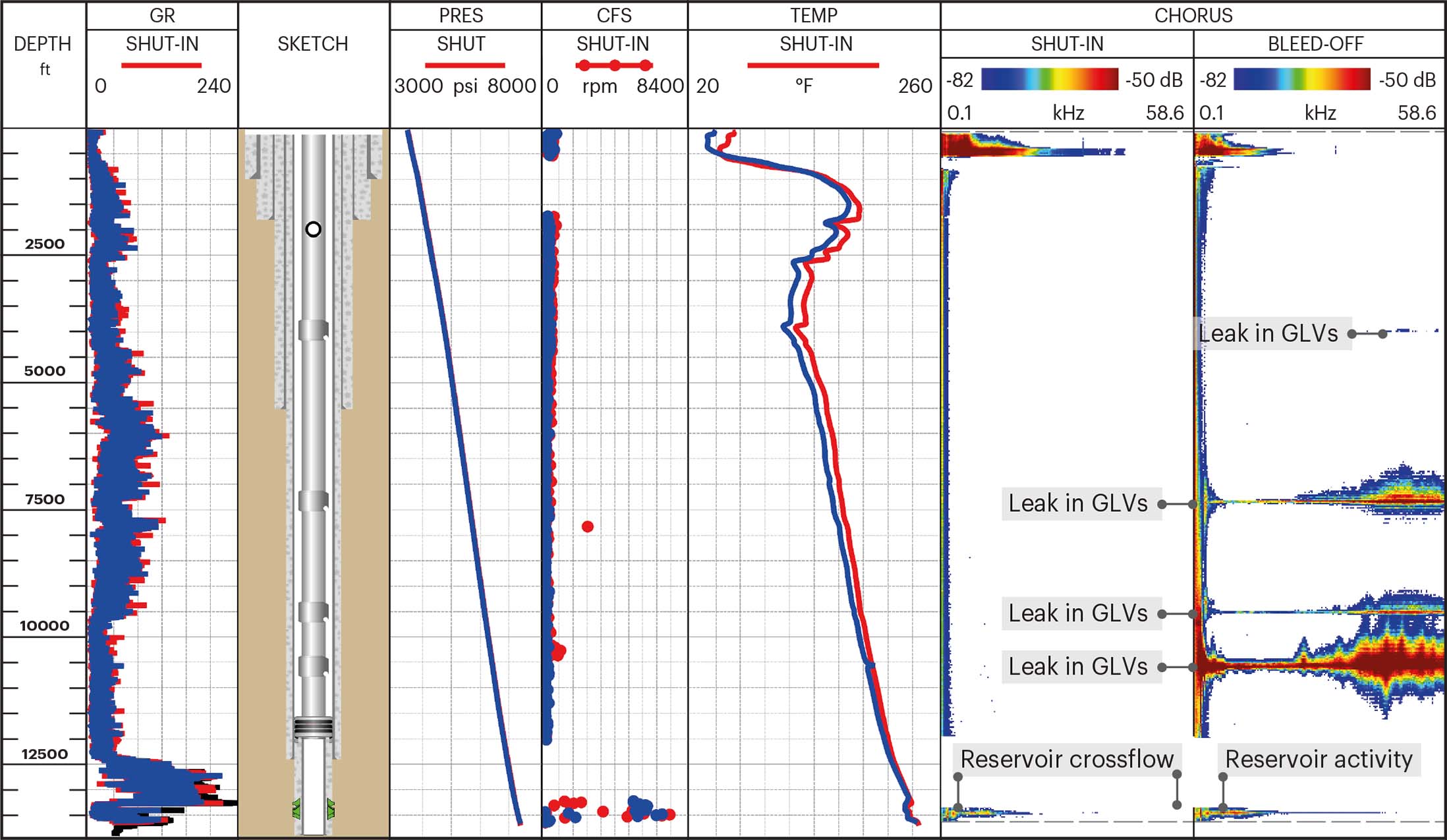

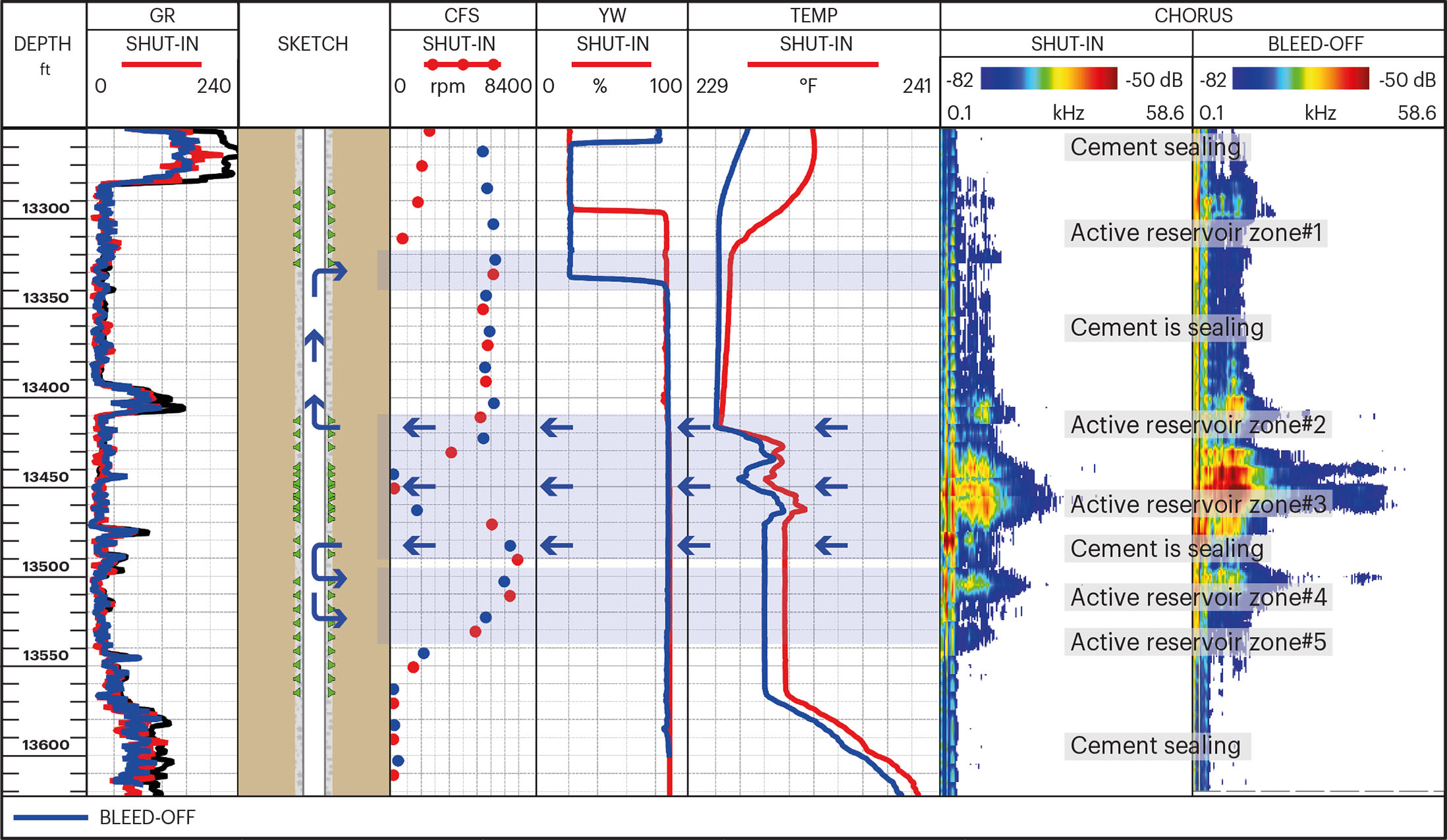

The gas-lift producer in this case study had been shut-in due to sustained annulus pressure (200 bar) and excessive volumes of H2S that could not be handled by the production facilities. The operator wanted to assess primary barrier integrity and guide a workover programme. Traditional diagnostics methods, such as production logging tools (PLT) and temperature logs, were deemed inefficient because they could scan only the production tubing and were unable to confirm the integrity of the packer and production casing. Identifying and shutting off the source of the water with high H2S content would protect the environment and deliver a production gain of 2,050 barrels of oil per day (BPD). Eliminating the production of highly toxic H2S and ensuring its containment within the well system would also deliver important environmental and safety benefits.

- Location UK

- Field Scott

- Well Type Gas-lift producer

- Customer Nexen (CNOOC)

- Reference SPE ICoTA European Well Intervention Conference 2019

-

Applied through-barrier diagnostics to guide efficient workover programme and restore primary barrier integrity.

-

Identified hydrogen sulphide (H2S) source and helped with isolation planning.

-

Optimised water shut-off to increase oil production and reduce water cut.

-

Enabled rapid, low-impact remediation to minimise resource use and emissions.

-

Characterised downhole failures that were not detected by conventional methods.