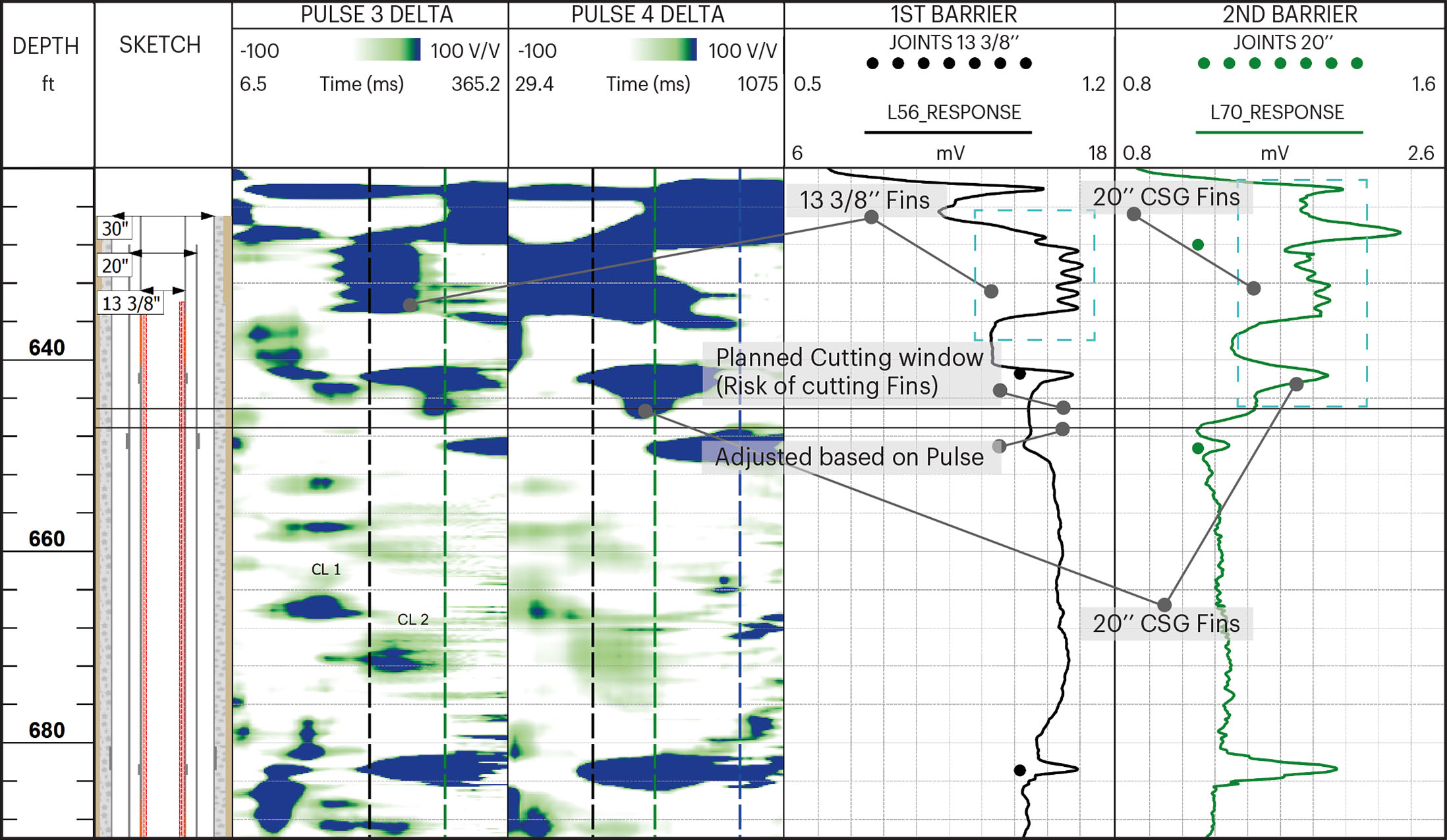

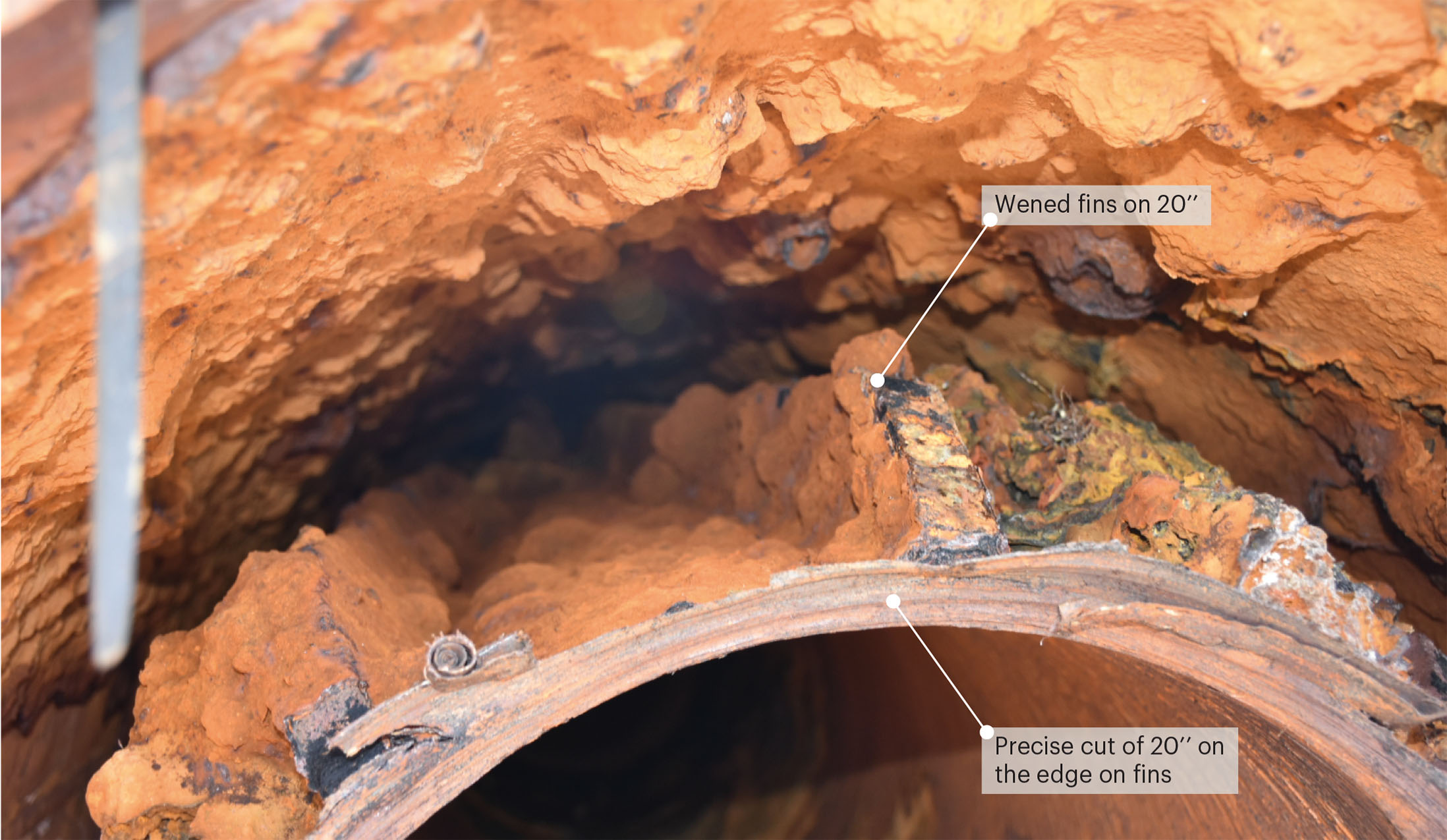

Setting surface plugs in offshore wells requires multistage cutting and pulling out of well casings. The milling process may last between a day and a week, depending on the well structure and the depth of the cutting window. The aim is to define the cutting interval so it contains the smallest volume of metal to be processed. The presence of collars, centralisers and welded fins can also substantially increase cutting time.

A multistage ultrasound survey is the conventional method for locating zones of minimal total wall thickness in the tubulars and determining the completion elements. This approach requires well preparations and logging after each stage of the retrieval process. The time spent on well preparation activities such as cleanout, pressure logging and interpretation is active rig time and a target for optimisation.