Made by experts for experts, Cascade3 builds on two decades of practical knowledge and experience applying science and mathematics to solving the most complex downhole flow scenarios.

The most powerful flow analysis platform ever created for horizontal well systems

Incorporating the industry’s most advanced thermodynamic and hydrodynamic modelling codes, Cascade3 transforms temperature, pressure, and other well system data into continuous reservoir flow profiles. Crucially, the flow profiles reflect flow activity in and out of the reservoir, delivering the truest picture possible of reservoir behaviour and inflow/outflow downhole.

The new Horizontal Flow diagnostics powered by Cascade3 overcomes many of the challenges faced by conventional production surveys, delivering a more reliable and complete assessment of flow dynamics in horizontal wells in a wider range of completion scenarios. Equipped with the right information, asset teams can take direct action to keep well and reservoir performance on track.

Modelling

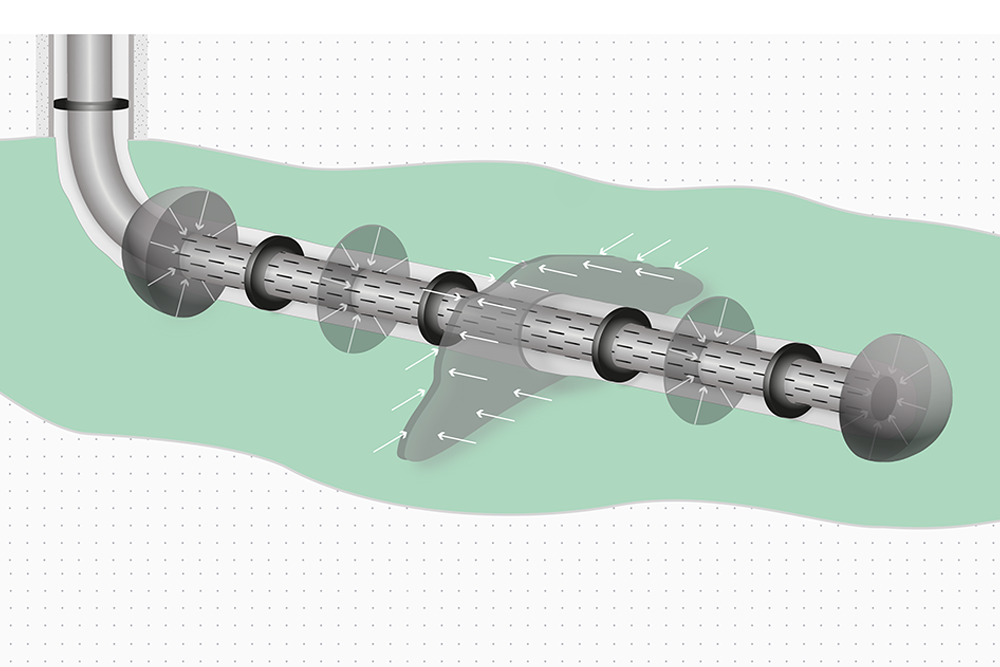

At the heart of Cascade3 is Torrent – a remarkable modelling and simulation engine that predicts the hydrodynamic and thermodynamic behaviour of fluids and their surroundings as they flow through the well-reservoir system.

Torrent features a unique 3D fine-grid modelling framework and can simultaneously solve three distinct flow geometries – radial, spherical, and linear in fractures – reflecting the three main types of flow that occur in a horizontal well system. Apart from providing a more realistic flow modelling environment, these features mean that Cascade3 delivers accurate continuous flow profiles in a wide variety of completion and reservoir settings, including fractured formations.

Features

Benefits

Production and Reservoir Engineers depend on downhole flow profiles to manage well and reservoir performance. Conventional wellbore production surveys can only sense certain flows entering the well completion and cannot measure inflow/outflow where it matters most – at the reservoir behind the completion. Also, even wellbore flow profiles can be compromised in open hole, and by viscous fluids, low flow rates and the complex flow regimes that occur in horizontal wells. Incorrect flow profiles can lead to missed opportunities and poor well and field management decisions.

Horizontal Flow with Cascade3 solves many of the diagnostic challenges faced by Reservoir and Production Engineers, providing them with the flow insights they need to reduce operating costs and energy consumption, and increase ultimate recovery.

Full benefits table found here.

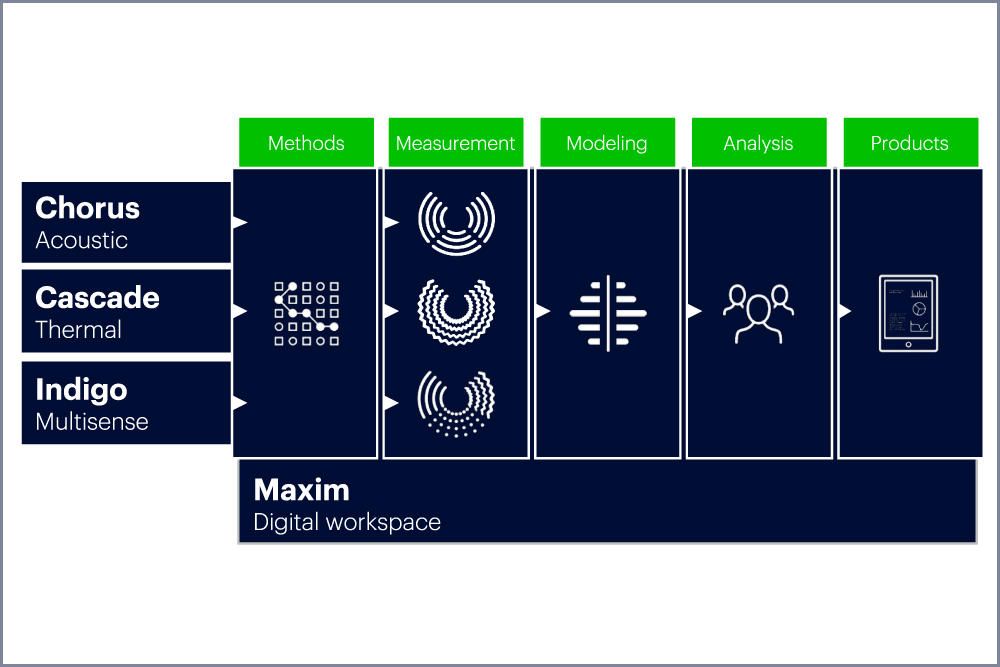

Cascade architecture

Platform partners

Cascade3 works alongside three other technology platforms—Chorus, Indigo and Maxim, that together constitute the True Flow diagnostic system. Each platform has a specific role in providing Horizontal Flow insights.

Whereas Cascade3 quantifies flow activity by modelling and simulating temperature and pressure changes in the well system, Chorus locates and characterises flow activity by sensing and imaging acoustic energy. For example, Chorus data can help the analyst distinguish between wellbore flow, reservoir or matrix flow and fracture flow, and provide a clear indication of active zones. And both temperature and acoustic data can help distinguish between liquids and gas.

Multisensory Indigo provides a host of wellbore measurements, including high-precision temperature that feeds into Cascade3, pressure, and a range of standard and unique production sensors, as well as real-time data transmission to the surface. Maxim is the digital workspace where analysts plan the diagnostic programme, integrate, and process the acquired data, perform the modelling and the in-depth analysis delivered in the final Horizontal Flow answer product.