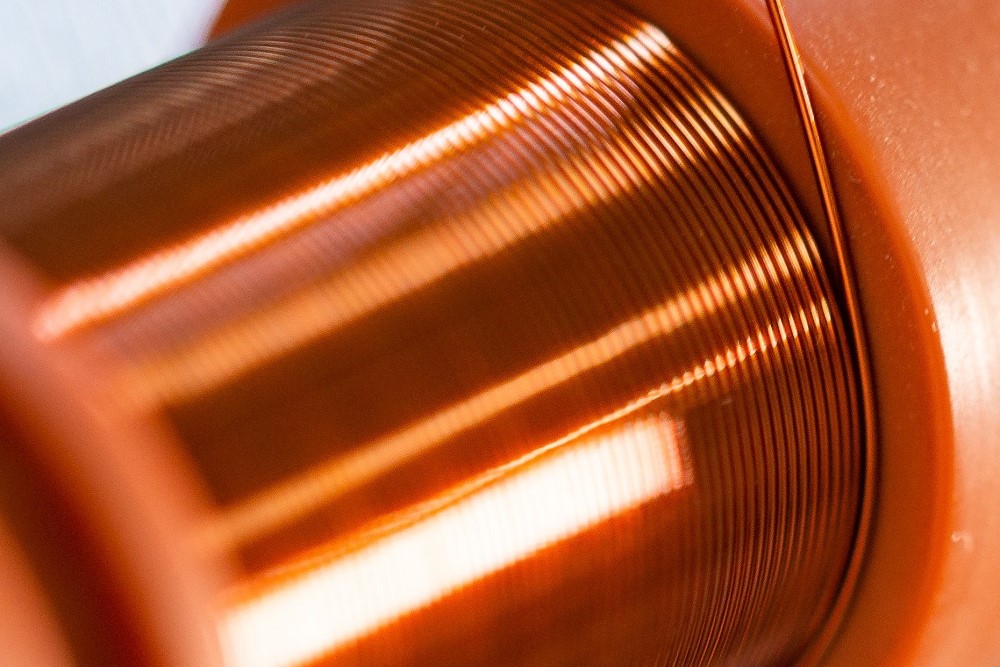

Pulse1 is the newest addition to our Pulse electromagnetic platform; one of five proprietary platforms that provide powerful through-barrier diagnostics to the oilfield.

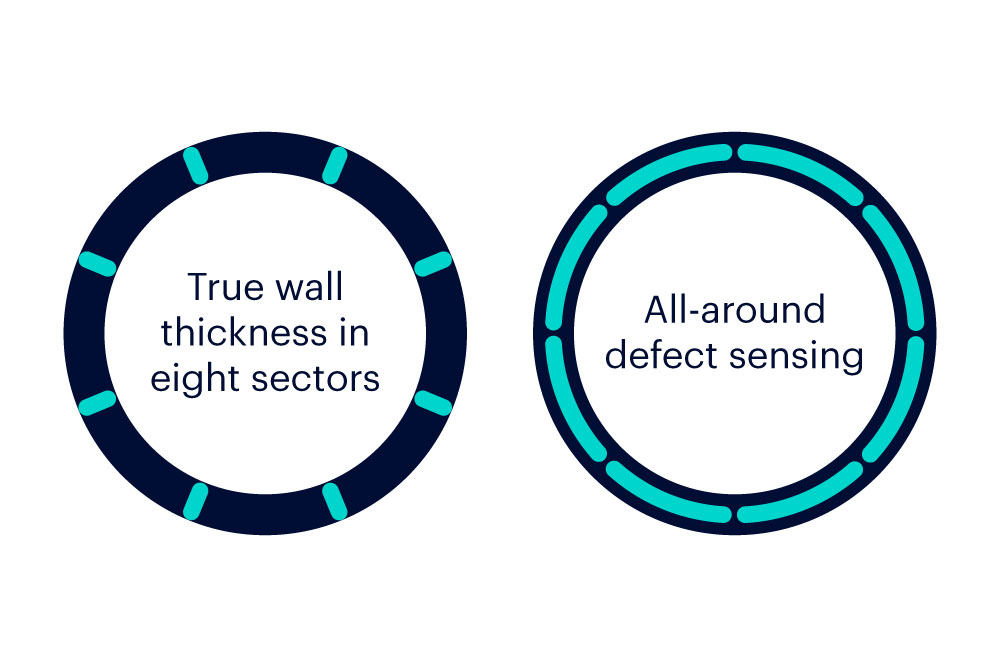

Pulse1 is the industry’s first slimhole tube integrity technology capable of delivering ‘true wall thickness’ measurements of production tubing in eight sectors, with complete "all-around" sensing of tube wall condition.

Pulse1 has been designed to meet the growing industry need for "no compromise" integrity management, and overcome the drawbacks of current technologies, especially multifinger calipers and conventional electromagnetics.

Calipers measure internal diameter and estimate wall thickness by assuming a ‘nominal’ outside diameter (OD).