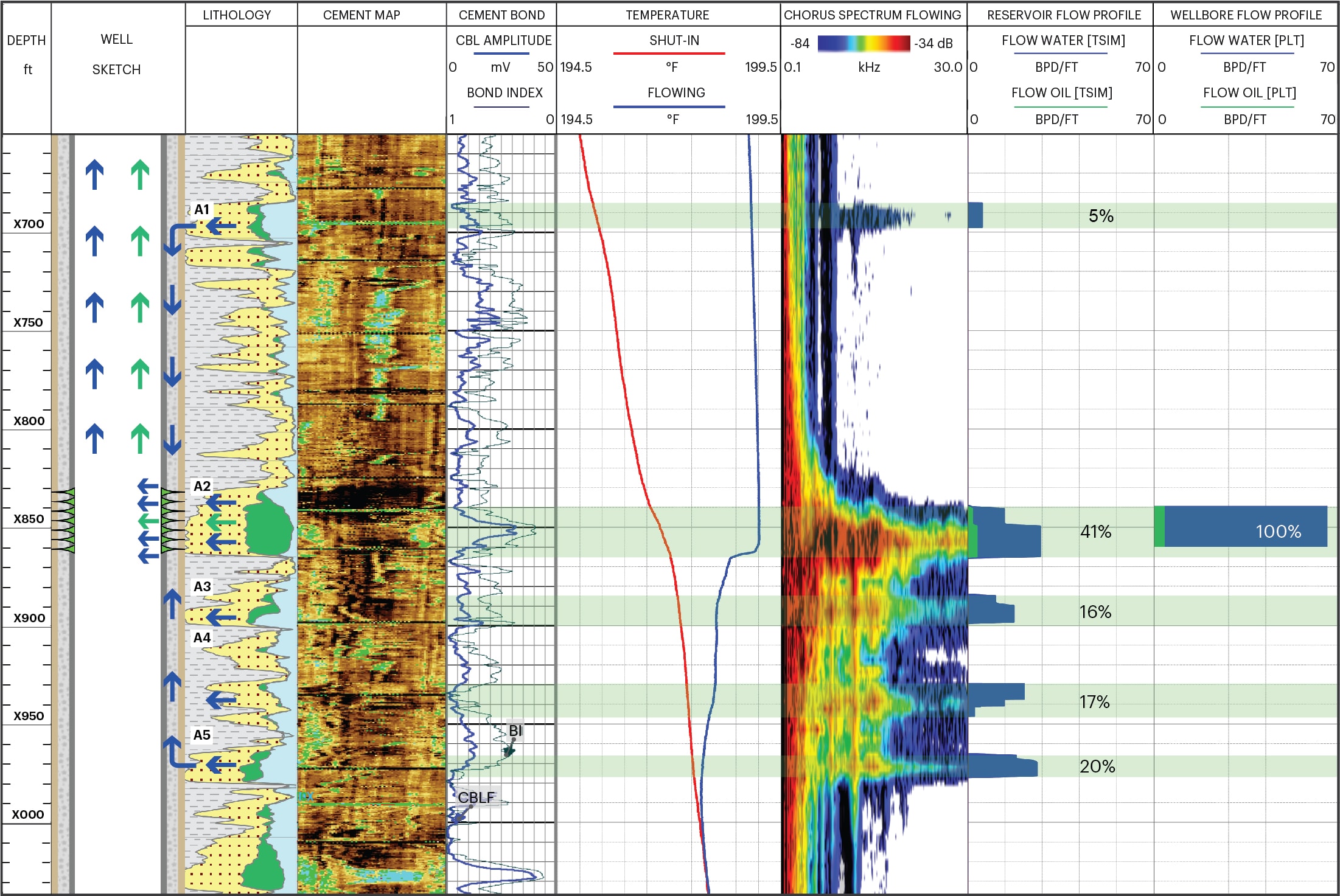

Identifying the source of high water-cut is one of the most urgent priorities for petroleum and reservoir engineers to resolve.

A deviated production well was exhibiting an extremely high 95% water cut and the operator needed to establish the precise source of water production in order to plan an effective remediation.

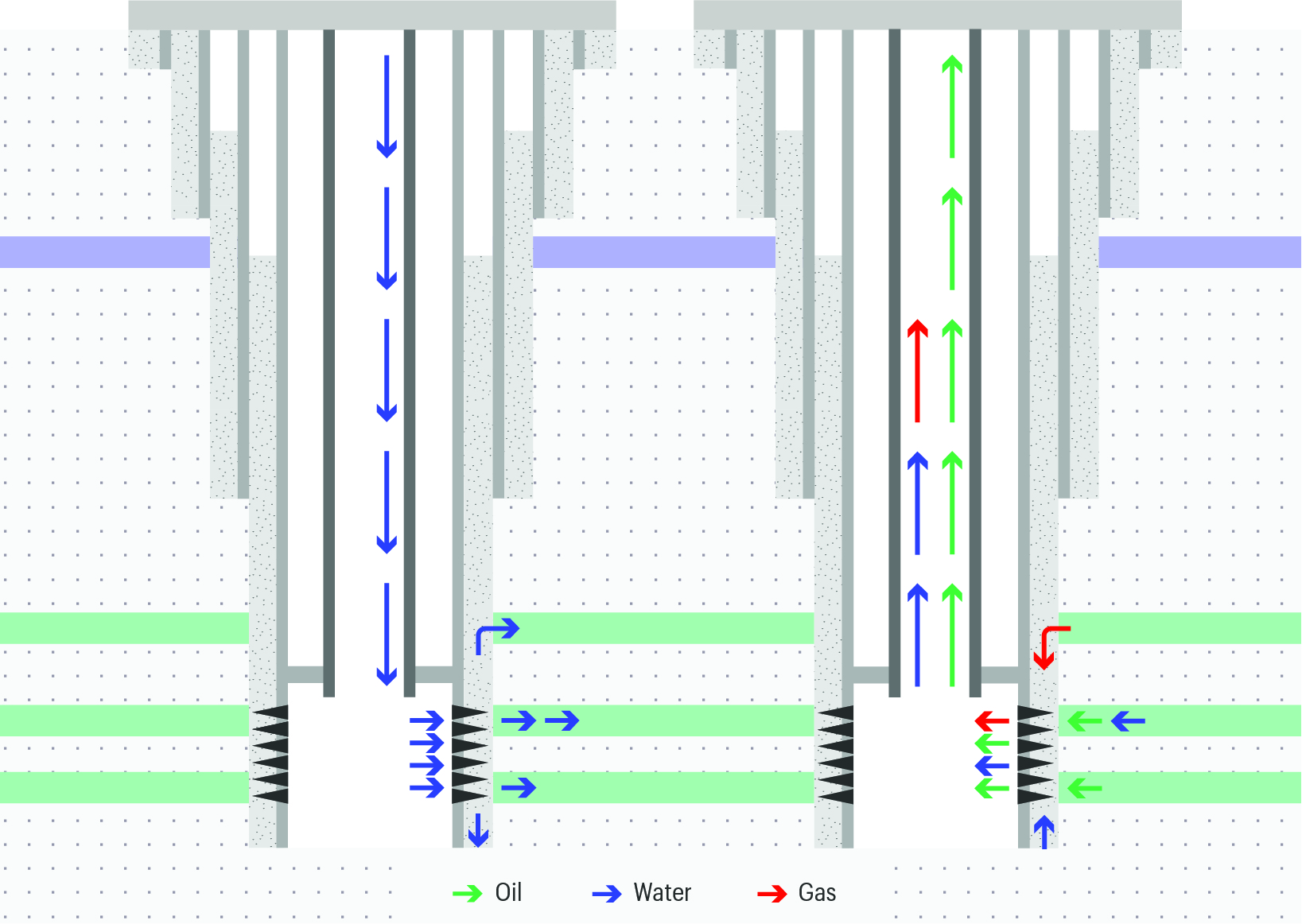

The operator was perplexed because the open hole interpretation indicated very low water saturation in the target reservoir, suggesting that the water may be coming from another formation, or that the reservoir was experiencing water break-through. Conventional production logging diagnostics [PLT’s] would show where the water was entering the wellbore, but not necessarily its true source behind casing.