Sand production from oil and gas reservoirs is a serious issue. It can decimate productivity and erode the integrity of well completions and surface assets. Often, the first indication of sanding issues downhole are the detrimental effects that can occur at surface, such as fill in separators or erosional damage to pipework.

Thru-tubing remediation typically involves an interval approach for a problem which may be localised. Historically, this is because there is a duality of issues in the ability to accurately identify the location of sand ingress and to target a localised fix. Surface monitoring can detect when sand is being produced, but locating the source and dynamics of sand inflow downhole is essential to protecting integrity and maintaining production.

Tendeka and TGT’s combined “Sandbar” sand remediation solution addresses all of these issues to offer a more precise, reliable and effective intervention-based solution.

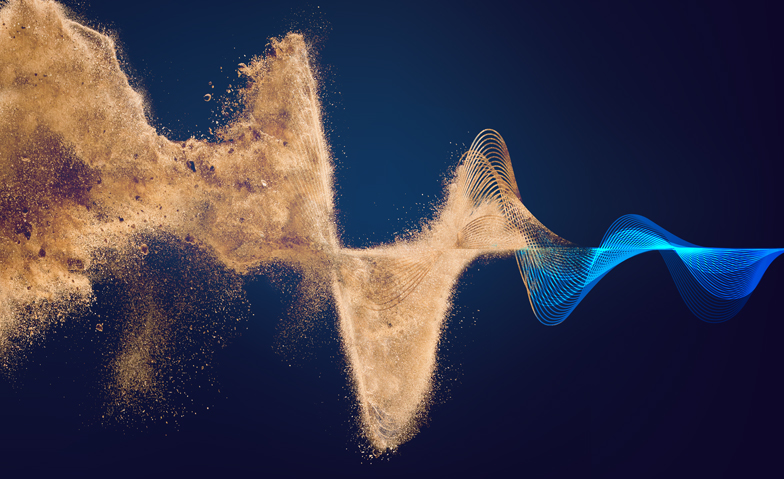

It follows a simple process flow of "Find, Fix, Confirm".

TGT’s Sand Flow product precisely locates sand entry to the wellbore and provides a quantitative sand count, whilst Tendeka’s Filtrex remedial sand control system is precisely targeted to repair the damage. Crucially, Sand Flow is then redeployed to confirm the repair.

Find

Sand Flow diagnostics are delivered using TGT’s “True Flow” system and the “Chorus” acoustic sensing platform. Chorus is deployed on wireline, capturing and decoding the acoustic signature generated by sand particles entering the wellbore and impacting the tool. It analyses the acoustic time-domain data to discriminate between sand flow

and fluid flow, thus locating the sand entry points and quantifying the sand rate.

Fix

Tendeka’s Filtrex is deployed into the well on coiled tubing and positioned across the target area. Dropping a ball in to the string allows pressure to be applied in two stages, firstly to set the anchor, and secondly to release the compressions sleeve. Upon removal of the compression sleeve, the matrix polymer expands to contact the wellbore and the deployment string can be retrieved from the well.

Confirm

The same diagnostics are run in the “Find” scenario, but this time deployed through the internal diameter of the Filtrex system to confirm that no sand is entering at that depth.