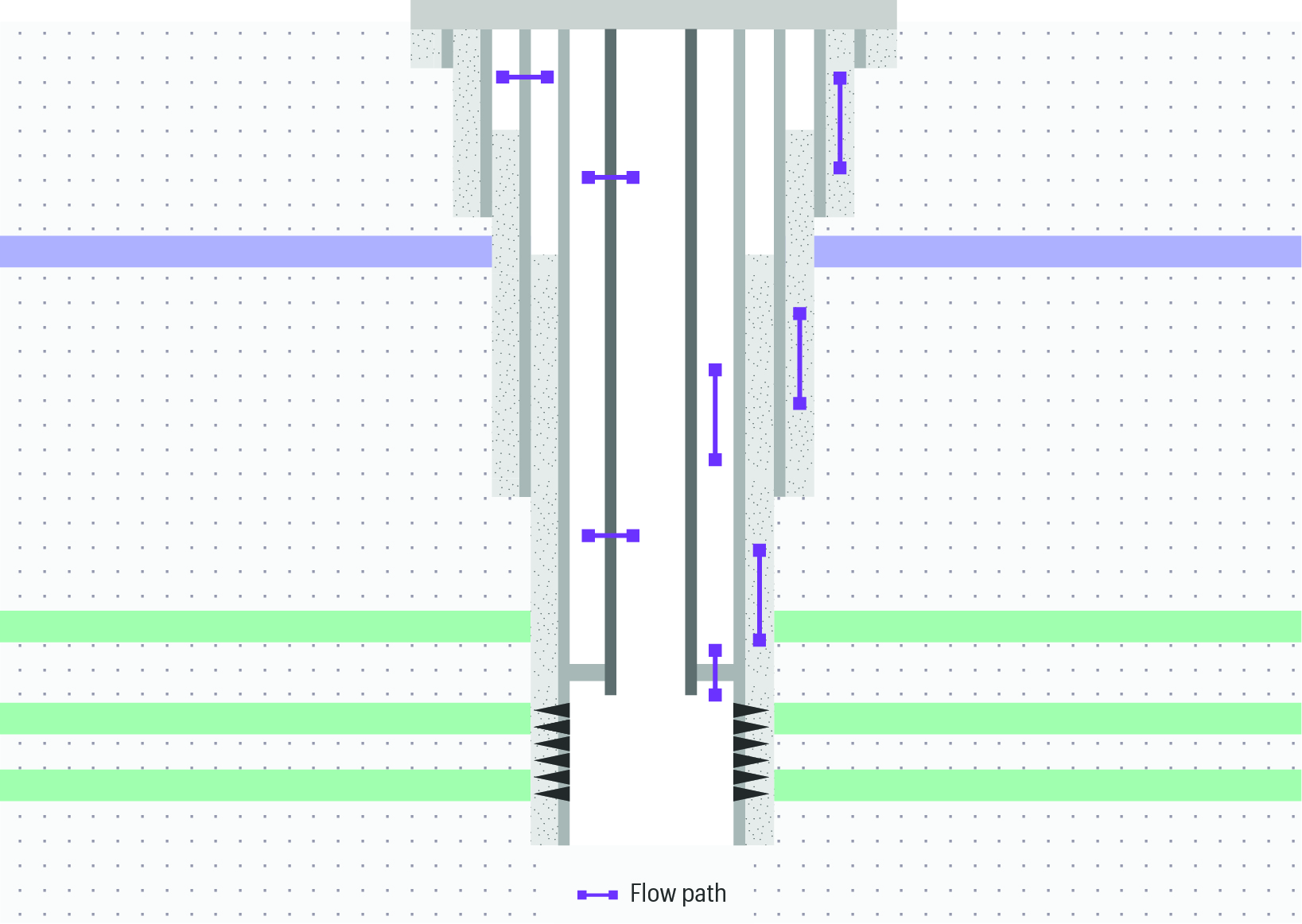

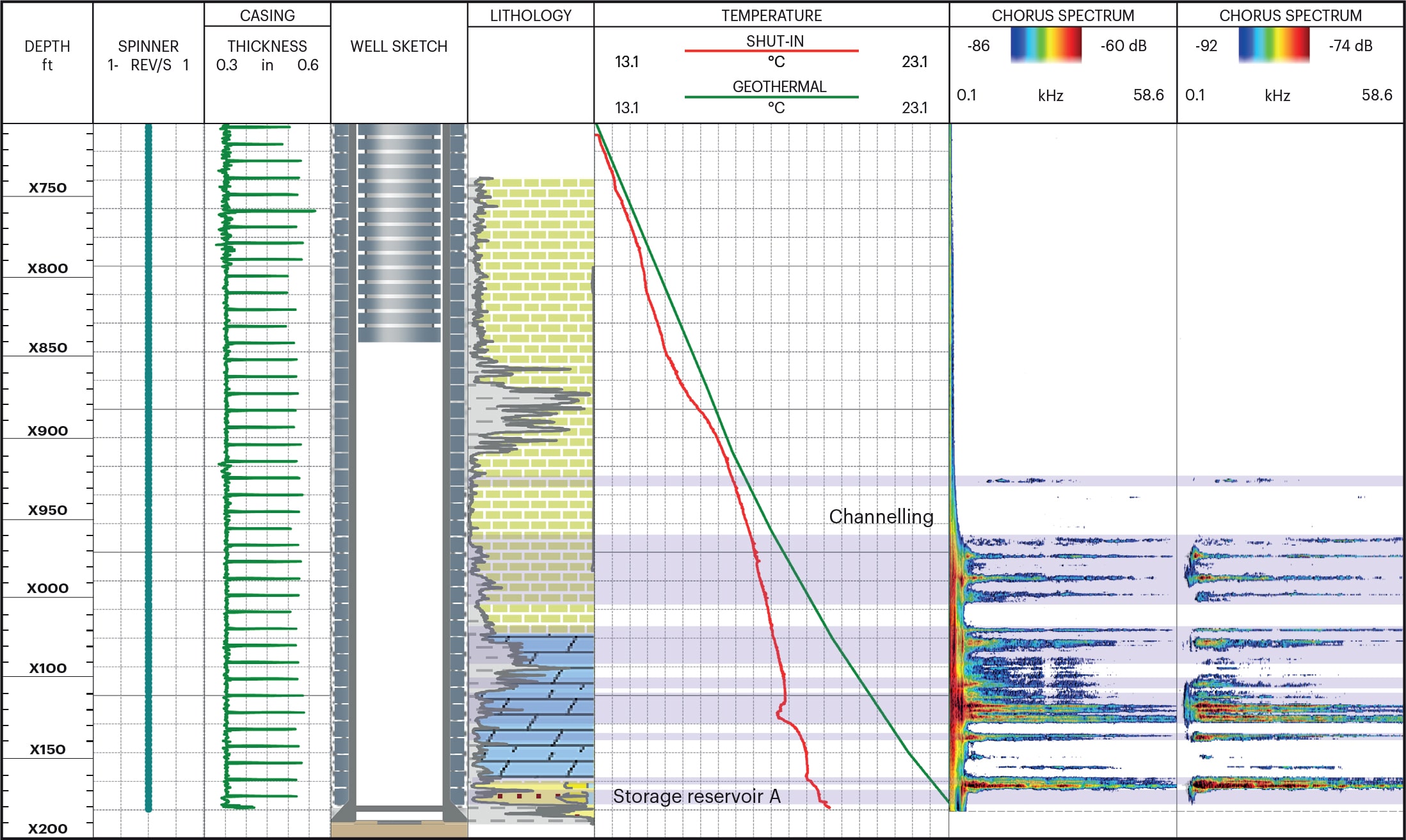

The integrity of underground gas storage wells is crucial to the safety and efficiency of gas supply operations. In this case, immediately following completion of a newly drilled well, the operator discovered poor quality cement in the production casing annulus. This was concerning because it allowed for the possibility of cross-flows behind casing.

The operator decided to check the integrity of the entire well to ensure that no gas was escaping from the gas storage reservoir into other formations. The operator needed a clear understanding of the nature and location of any cross-flows to target an effective remediation programme.