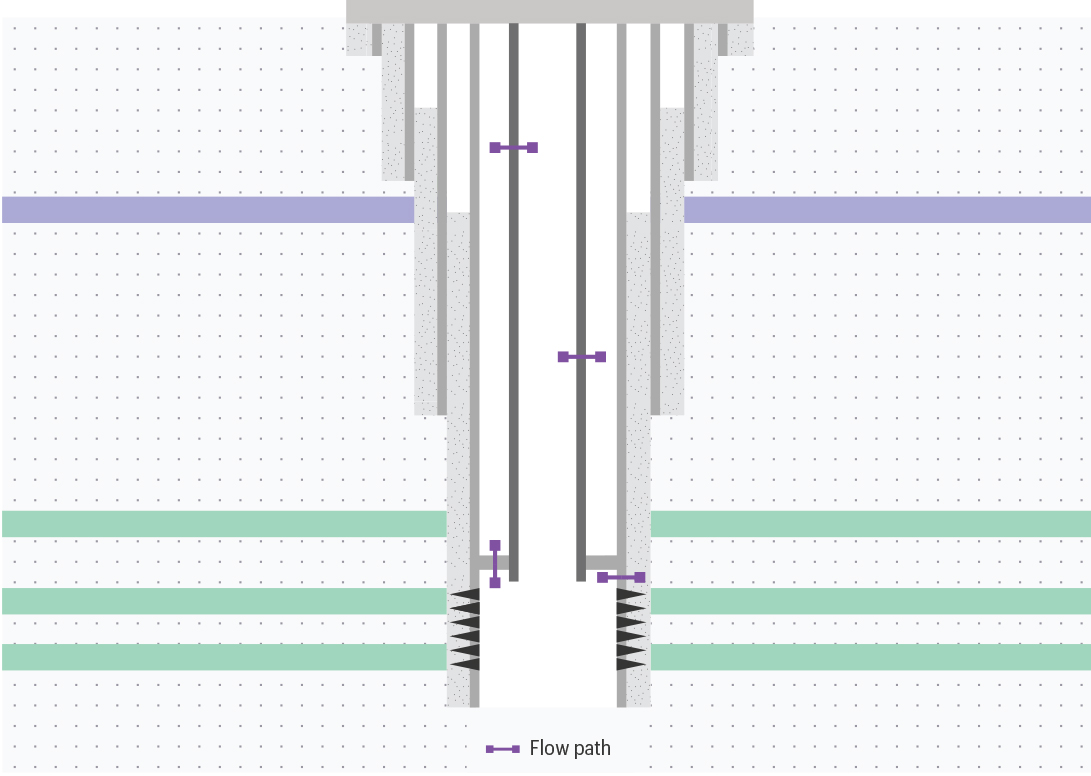

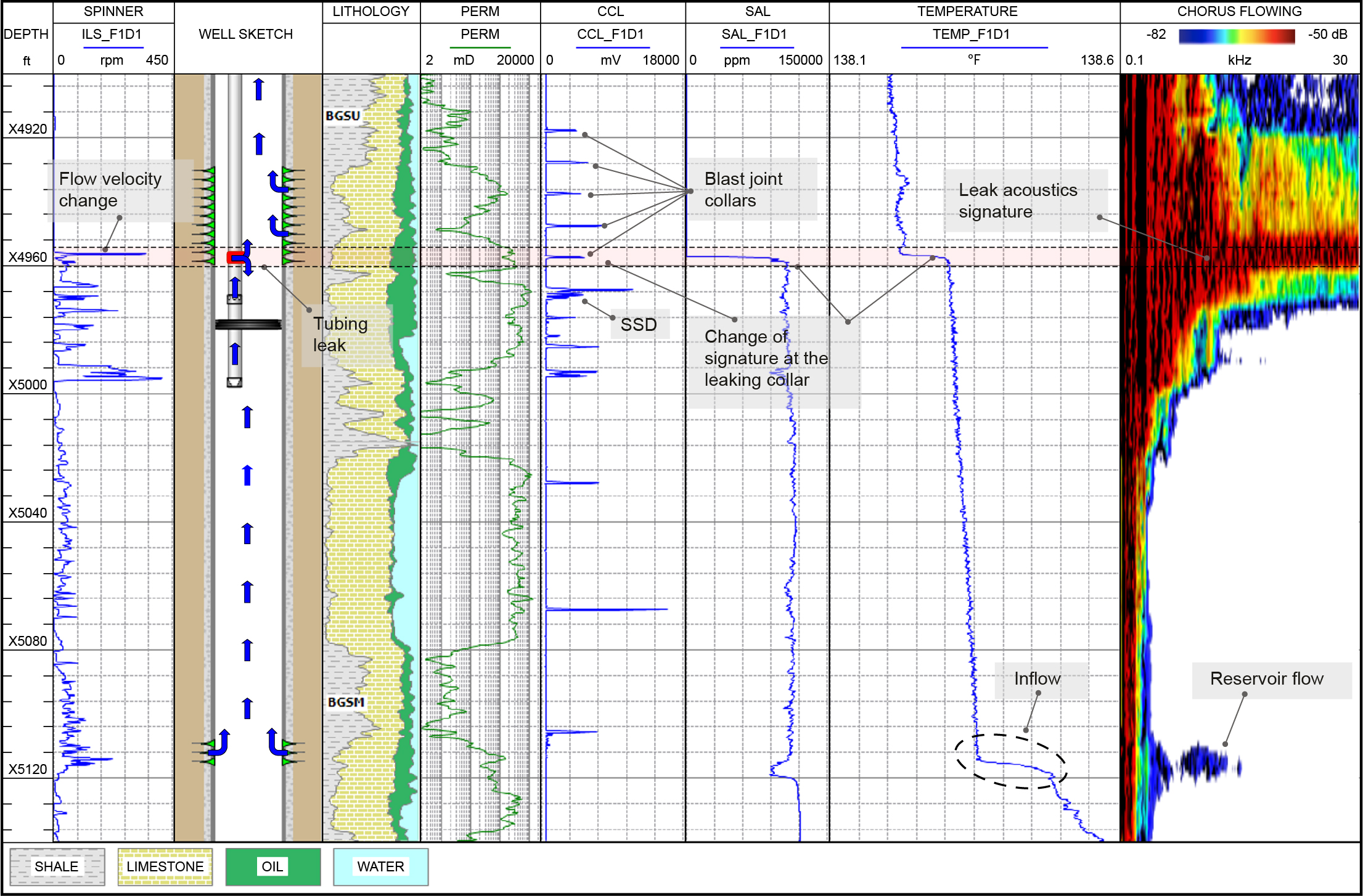

Primary barriers are key for protecting the integrity of a well system. When failures occur in these barriers, they must be diagnosed quickly to avoid unsafe operation, lost production and the risk of escalation. Leaks in wellbore tubulars can lead to unwanted fluid communication between reservoirs that can result in substantial production losses for oil and gas operators.

The subject well in this study is a naturally flowing oil producer that was producing from the top reservoir through the short string while the bottom reservoir, producing from the long string, had watered out and ceased to flow. A sudden increase in water cut at surface prompted the operator to investigate.