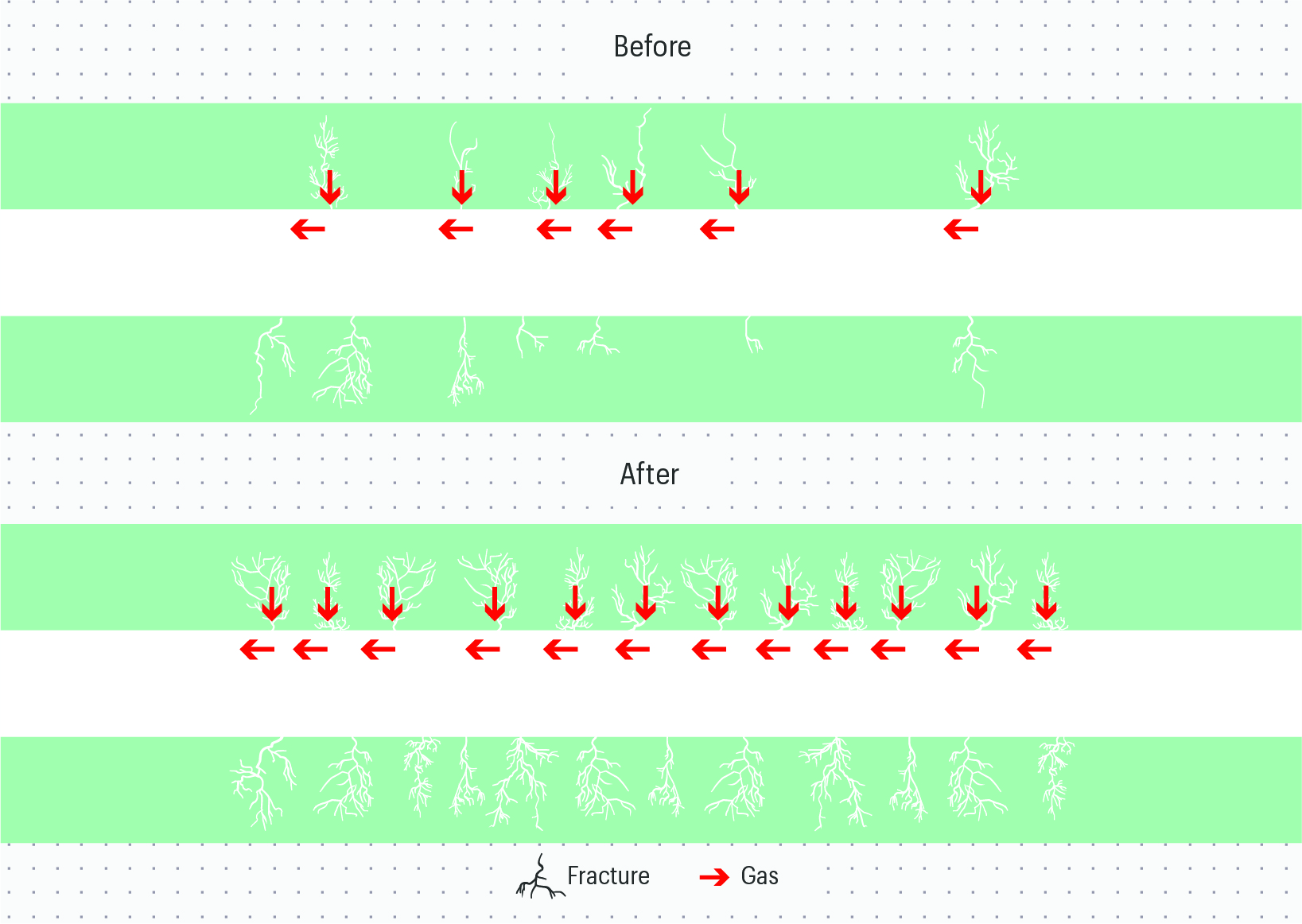

Multistage fracturing is an effective stimulation technique for heterogeneous, low-permeability oil reservoirs. However, after a fracturing campaign, there may be a risk of increased communication between the water-bearing formation, which may cause a high water cut in the stimulated well.

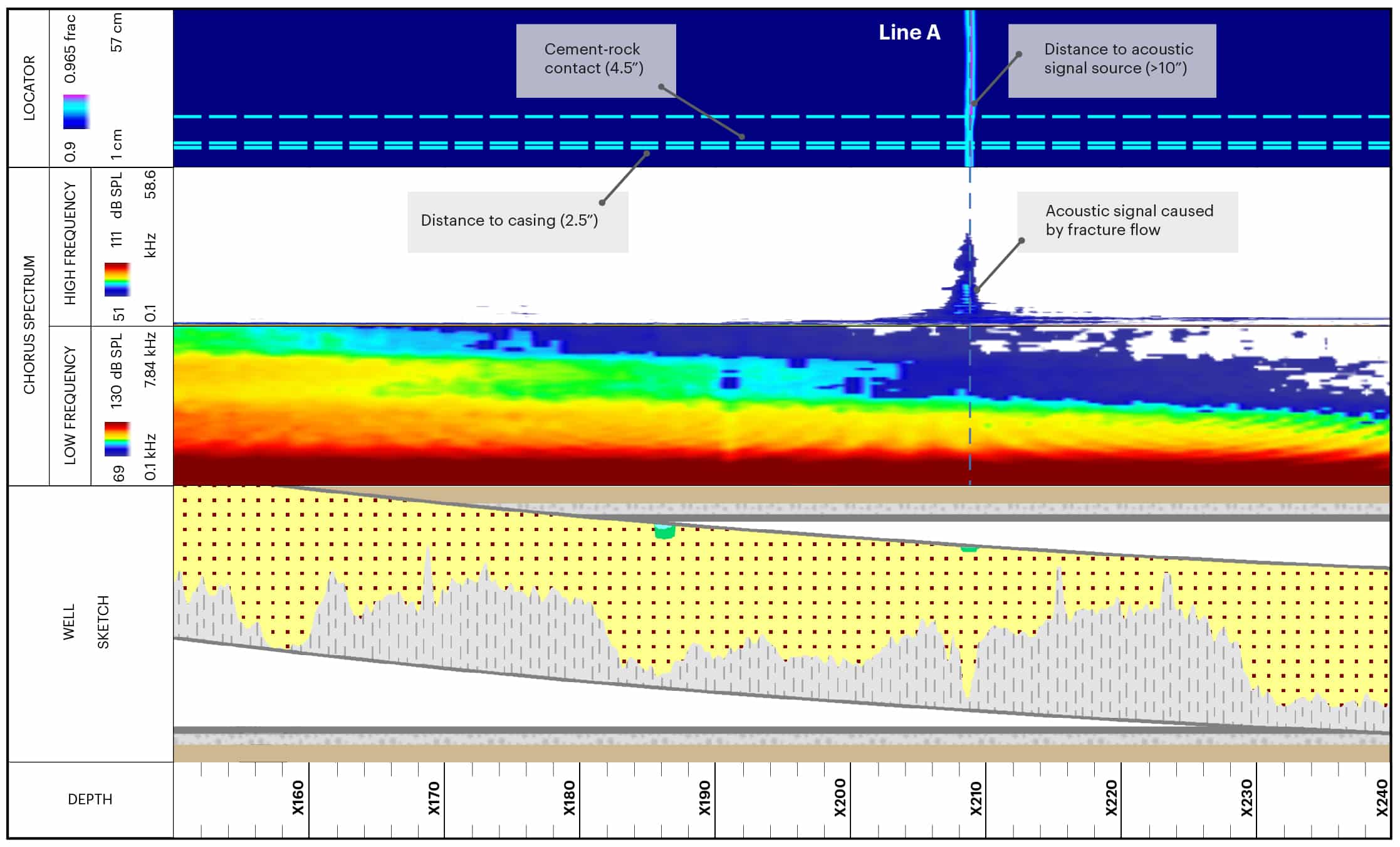

In this case from the Volga-Ural region of Russia, the operator wanted to identify unexpected water sources in a horizontal well in a low-permeability carbonate reservoir. The well had been subjected to a multistage acid fracturing job and it was necessary to determine the most effective strategy for a workover to shut off the water producing zones.