TGT announced today the release of its real-time Indigo platform, significantly expanding the range of benefits brought by its family of powerful through-barrier diagnostic systems. The new real-time technology enables well data to be viewed and analysed at surface during the execution of well diagnostic programmes without compromising on measurement fidelity. This will bring several benefits to customers, including improved data quality, enhanced intervention efficiency and faster remediation decisions.

Ken Feather, TGT’s Chief Marketing Officer commented, “Real-time data isn’t new to the oil industry, but currently available transmission systems couldn’t meet our exacting data quality standards—so we developed and built our own high-fidelity system. In doing that we have taken conveyance and decision-making flexibility to an entirely new level for our customers, with no compromise on measurement quality. As a result, we expect the popularity of our diagnostic systems and products to expand even further.”

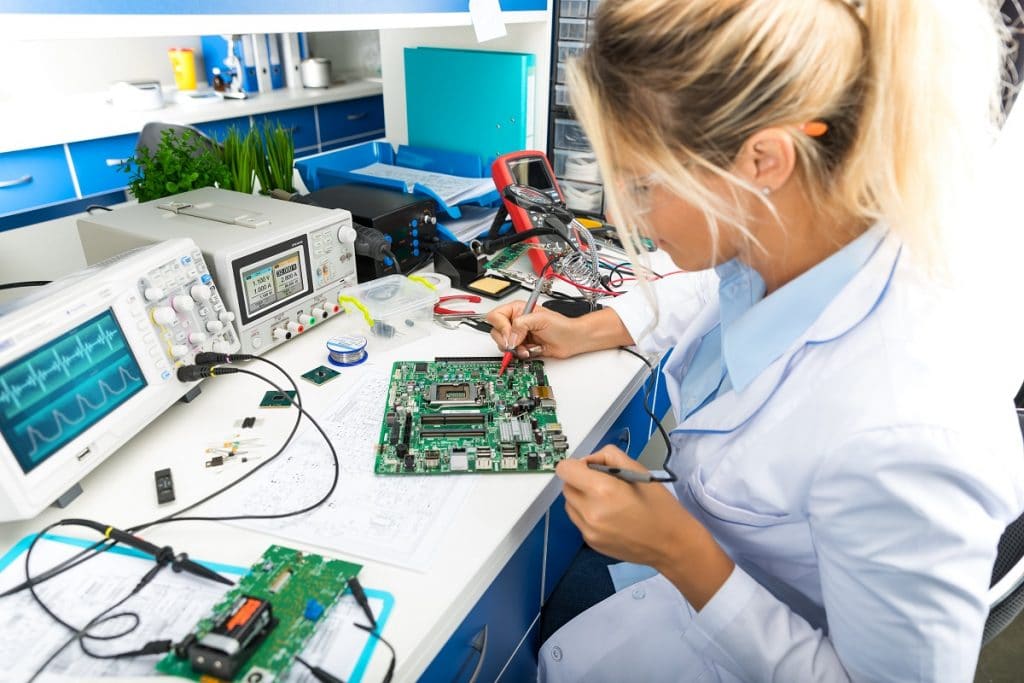

TGT creates all its own hardware and software in-house and follows a strict philosophy of ‘fidelity’ in the design and manufacturing of its diagnostic sensor technology and instruments. This philosophy is clearly embodied in its ‘Indigo’ platform of complementary sensors and auxiliary equipment. Indigo technology is distinctly ‘low noise’ and custom-built to operate perfectly with TGT’s through-barrier suite. The new real-time capability is particularly relevant to TGT’s acoustic-based ‘spectral’ and electromagnetic-based ‘EmPulse’ diagnostic systems, which lead the industry in diagnosing flow and integrity dynamics within oil and gas wells, helping operators to improve well performance.

Traditionally, through-barrier diagnostics are performed using ‘memory-mode’ deployment. With a track record of 20-years and an efficiency of more than 99%, TGT’s memory-mode deployment remains a flexible and popular choice across the industry. With this approach, diagnostic information is accessed when the measuring instrument is retrieved from the well. However, with real-time access, data can be viewed during the diagnostic intervention and streamed remotely from the wellsite enabling a host of benefits, such as dynamically adjusting the acquisition program, and making faster decisions.

Artem Buharaev, TGT’s head of Indigo development also commented, “We have overcome many technical challenges in commercialising our real-time Indigo platform. Existing data transmission technology available within our industry generates unacceptable levels of acoustic and electromagnetic [EM] ‘noise’, that would otherwise degrade our highly-sensitive sound-based and EM-based measurements, so we developed our own design that was both ‘quiet’ and fast.”

The real-time system comprises of a downhole Indigo modem module and a surface interface unit that enables two-way communication between surface recording equipment and the downhole instruments.