Article featured in Harts E&P

When oil prices fell in 2014 exploration and production (E&P) companies were forced to tighten capital budgets, reduce activity levels and drive down costs. The ensuing stampede to cost reduction hit upstream oilfield service companies extremely hard.

Today, with the oil price stablising, operators are more inclined to push their assets harder to produce more. However, when budgets were slashed, planned maintenance and workovers were amongst the first to be cut or deferred, while still treading the line not to compromise on safety. Securing asset reliability is still a top priority, ensuring that wells perform at full capacity while safeguarding life and the environment.

“Wells need to perform better and last longer. Operators need to elevate well performance and need the ingenuity of oilfield service companies to do this more effectively”, comments Mohamed Hegazi, Chief Executive Officer, TGT. “In today’s economic climate we have an obligation to challenge the old way of thinking by being bold and innovative so that customers can capture more value and address well performance challenges more readily.”

For all asset managers, a key area of vulnerability lies in the happenings thousands of meters away from the surface—downhole.

Like a giant industrial plumbing system fused into the earth, wells are built using a fantastically complex assembly of tubes, barriers and cement, most of which exist around a central producing conduit. Their sole purpose being to transport valuable fluids safely, productively and profitably.

Unfortunately, we live in an imperfect world where natural forces conspire to undermine the perfect functioning of the well, and despite the ingenuity of man, the well will inevitably misbehave or fail. Naturally, the industry is obsessed with ‘wells’ and ‘reservoirs’. But conventional definitions and diagnostics of ‘the well’ tend to isolate the well completion from the reservoir, and yet the two are so inextricably linked they should never be separated – they work as one.

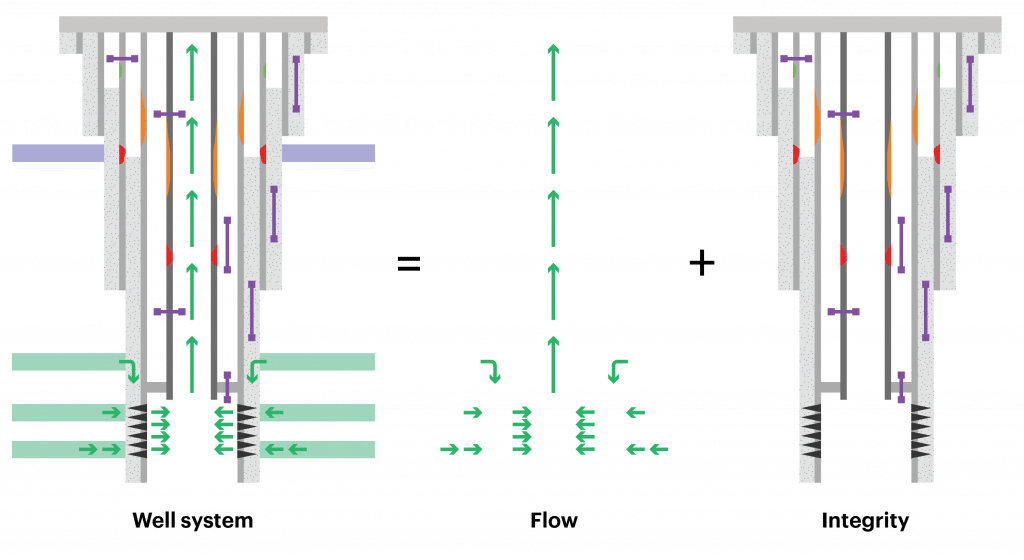

A new definition of the well is therefore needed. One that recognises the performance attributes of the completion and the reservoir it connects to, the interplay between the two, and the dynamics of the entire system. In fact, what we are dealing with isn’t just ‘a well’ – it’s ‘a well system’.

But that’s not enough. We also need to recognise the two most vital performance factors of all well systems—flow and integrity.

‘Flow’ is about the right fluids connecting to the right places, and ‘integrity’ makes sure that happens—without compromise. So, managing well system performance effectively means managing flow and integrity – and not much else matters.

“Diagnosing well system performance is challenging. Flow and integrity issues can exist anywhere within the well system; beyond the wellbore, behind multiple casings to the outer reaches of the well system, and in the reservoir itself—a place virtually impossible to deploy diagnostic sensors”, adds Mohamed.

Conventional diagnostics can’t provide all the answers because either they don’t look far enough, or measure the right things—they don’t look at the big picture. Rogue happenings, such as active thief zones, cross-flow or the source of sustained annulus pressure lurk behind barriers and wouldn’t be diagnosed with traditional techniques.

Flow and integrity, and therefore well system performance, can only be properly understood and managed by assessing more than the inner workings of the wellbore. This concept is the foundation of a new and important oilfield category, applicable to all wells—through-barrier diagnostics.

Diagnostic tools that ‘sense through barriers’ have existed for decades and overlap into this category, but apart from a few exceptions these have been chiefly concerned with investigating reservoir properties, such as matrix and fluid parameters, or evaluating cement.

Acknowledging and advancing through barrier diagnostics as a new category allows us to look at the well system in a far more holistic and uncompromising way. Seeing through multiple barriers from the wellbore into the reservoir and everything in between reveals more than ever before. Viewing the well system in its entirety provides operators with a more complete picture of the goings on, both flow and integrity related. And equipped with better insights, operators are much better placed to make the right decisions to keep the entire system working harder.

Maintaining safe, productive and profitable operations means that all well systems at some point will require diagnostic intervention, either for routine monitoring or to target a specific issue.

When it comes to diagnostics, ‘tools’ tend to dominate oilfield conversations, technical forums and procurement practices, and the operational focus tends to be on ‘running the tool in the well’. If a well system is experiencing unexpected sand flow, ineffective stimulation or fracturing, or sustained annulus pressure, the operator commissions a service company to deploy a certain tool in the belief that the tool itself will provide all the answers. But the reality is not that simple.

In isolation, the tool gives raw data and measurements, but revealing the truth about the well system requires more than the tool. The tool’s sensitivity and accuracy is extremely important, but many other factors beyond the tool contribute to the overall diagnostic result.

The synergy happens in all facets of the service, not just the tool; the diagnostic programme that activates the well, and the method for acquiring the data, the processing and modelling to refine and expand raw data, and the expertise in analysis and interpretation, all play a vital part. The results and insights materialise from the combined effort of all these factors—an entire ‘diagnostic system’, curated and applied by human experts.

There is no doubt that advancing diagnostics to deal with today’s challenges means evolving from tools to diagnostic systems on all fronts. But we need to go one step further.

When a well is exhibiting problems, what the operator ultimately needs is answers. Obviously, there’s an interest in making sure that the right diagnostic system is utilised, but the purchasing decision should be ultimately based on the clarity and completeness of the answer, because this is the final ‘product’ in the diagnostic workflow.

Consider the case where a well suddenly exhibits flow issues, such as a dramatic increase in water-cut, or complex integrity issues such as sustained pressure in the C-annulus. Then the operator is more concerned about getting an answer it can trust to solve these issues, not what tool or system to use.

“An application-led ‘products’ approach versus a traditional ‘tools’ approach allows for improved product selection and commercial flexibility, benefiting operators on both counts. Operators certainly appreciate technology but are ultimately seeking diagnostic answers that can help them make better decisions”, summarises Mohamed alluding to the approach TGT has adopted.

He adds, “A mechanism should be adopted where simpler products, such as diagnosing wellbore flow, that demand fewer resources and less innovation command a lower price. Whereas more complex products—like multi-barrier diagnostics, that have years of research and development behind them, demand more extensive resources, and ultimately deliver more value, naturally command a higher price.”

The old thinking can’t answer today’s new challenges. As well systems become older and more complex, managing performance will remain a priority and continue to task the industry. That’s why we need to innovate on all levels. Not just by building better tools, but by creating better diagnostic systems and recognising the experts that empower them. We need to acknowledge the dual importance of flow and integrity as the key enablers for asset performance, and the criticality of through-barrier diagnostics as the only means to see the true picture. And last not least, we need to adopt a product-led approach to procurement, where the answer is king, and not the tool. Do all that and the future looks bright.