Article featured in Harts E&P Magazine

Today, more and more wells are reaching the end of their economic life and need to be decommissioned—a process often referred to as Plug and Abandonment (P&A). Many factors need to be considered when designing an effective P&A operation, especially those that relate to barrier integrity, such as cement bond quality, the presence of behind casing flow, and potential inflow zones. Oil and gas producers are obligated to perform P&A operations in accordance with regulations and guidance typically developed in collaboration with government bodies to ensure that decommissioned wells and safe and secure.

The main objective of P&A is to restore previously penetrated natural barriers by securing potential barrier failures within the well system. These failures could be related to steel or cement barrier degradation during the operational phase of the well. Steps are taken to verify the sealing capacity of so-called external well barrier elements, including cement bonding, shale or formation creep, and baryte sediments. For offshore wells, re-entry of decommissioned wellbores becomes virtually impossible after a new lateral has already been drilled or when topsides have already been removed. Therefore, it is critical that the well is robustly and permanently sealed.

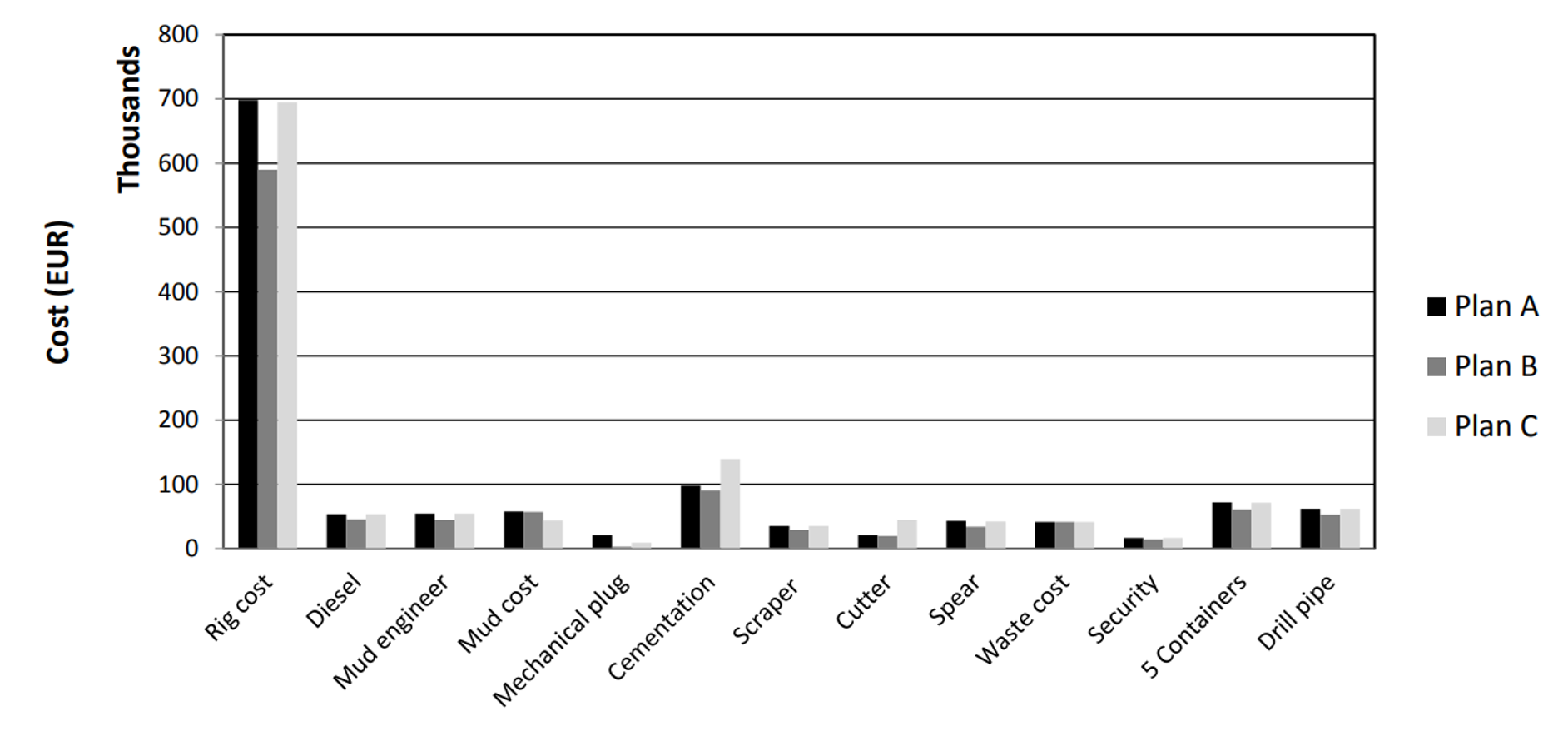

The resources required and cost of planning and performing a P&A operation are mainly driven by the complexity of the P&A, including whether it can be done riglessly or with a drilling rig. The operator has to strike a balance between meeting the required regulatory needs, deploying the required diagnostics tests, and optimising the time spent to prepare and execute the process.

This P&A cost is not an investment into future profit. It is an investment in protecting the environment and eliminating future hazards. In order to address all concerns, operators are seeking alternative solutions to improve the efficiency and effectiveness of P&A operations by reducing cost and at the same time increasing the reliability of operations.

Today, ‘P&A optimization’ is developing in two main areas:

- A transition towards ‘rigless’ mode, where P&A operations are performed using slickline, wireline or coil-tubing before the rig moves to the well. Rigless operations may include the abandonment of the reservoir, verification of the well barriers and gathering the input parameters for P&A sequence improvement. The key advantage here is to verify the existing well barriers when the tubing is still in the well. There are recent developments in tubing cement logging (spectral acoustics and through tubing ultrasound), enabling the evaluation of cement bond and seal with certain thresholds to determine barrier isolation.

- Utilization of alternative or natural barriers instead of conventional cement barriers. This allows P&A engineers to consider shale and formation creep, salt dome, squeezing bismuth and polymers to improve the sealing of the external well barriers and take the reliability of the barriers to the next level. The main advantage that operators see today is that shale, for example, may work as the best downhole barrier, because it does not degrade with time, has close to zero permeability, and may even seal potential future leaks or failures. In fact, simple calculations show that 30 m average cement barrier (as per NORSOK and U.K. P&A guideline) with permeability of 20 micro darcy will start to leak at a rate of 0.25 m3 gas a year if 1,000 psi pressure is applied. A similar leak rate for typical shale creeps permeability will only be observed in the presence of 2-5 m of well-bonded shale. The same 30 meters of shale will be almost impermeable (link to the presentation).

Operators typically plan P&A processes years in advance and develop the strategies individually for each well, taking into account the construction of the well, lithology and the technologies available on the market today. Above all, the strategy should meet the requirements of the regulatory bodies of the country in which the operator abandons the wells, as well as the operators own policies.

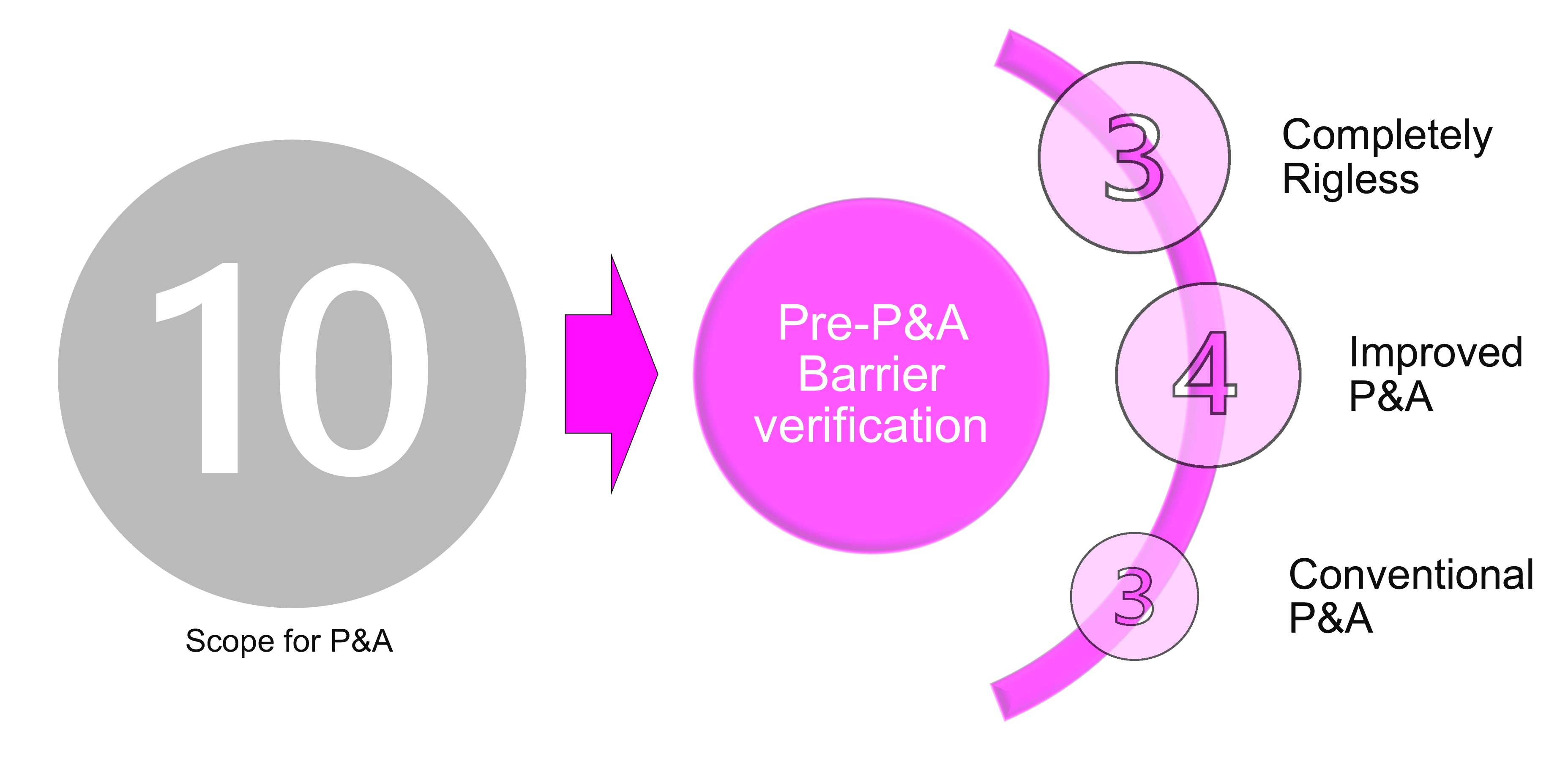

The example below shows the experience of a North Sea operator in using ‘P&A optimization.’ To improve the P&A process and demonstrate the ability of natural barriers to withstand reservoir pressure, the operator performs a test of the shale barriers for future abandonment.

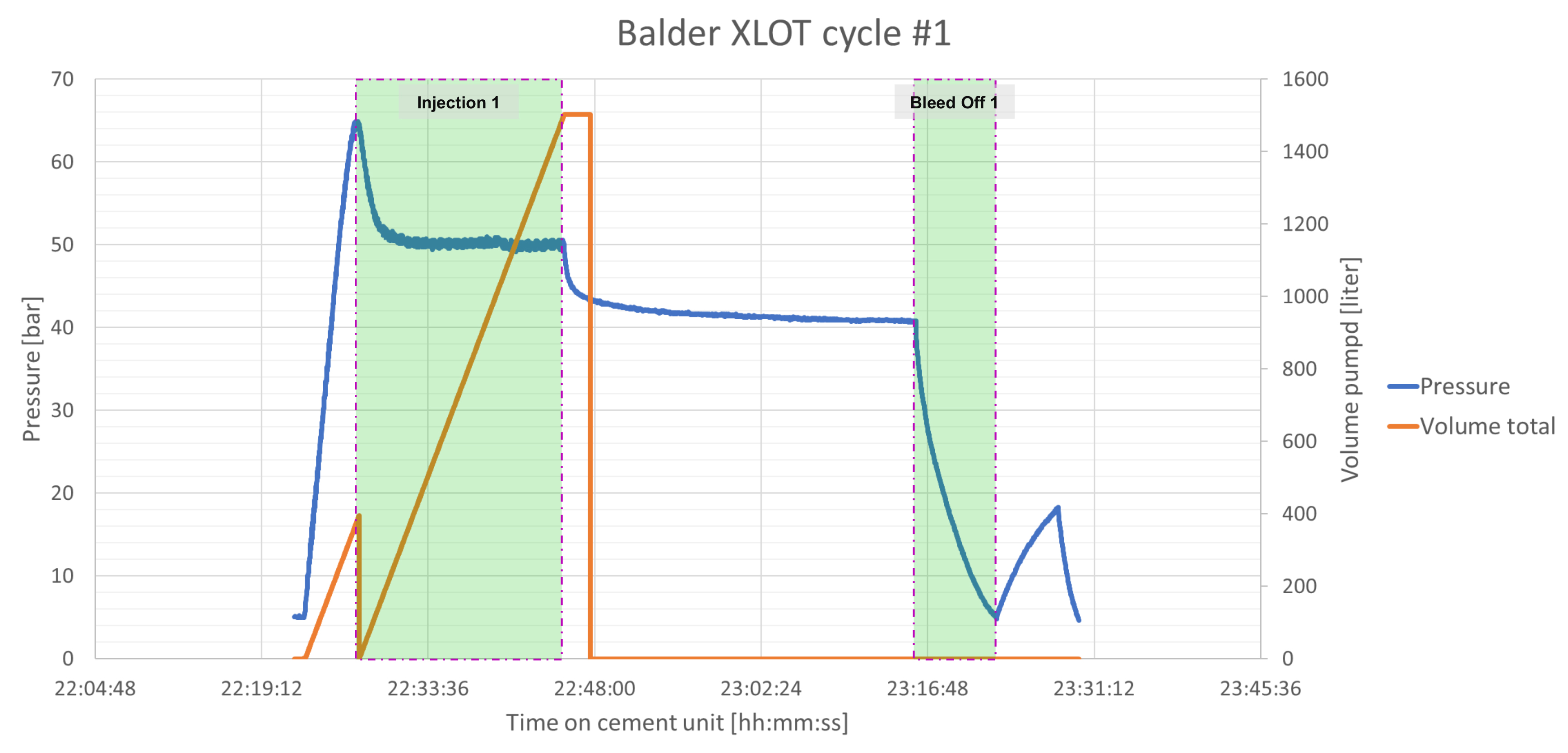

For a particular field on the Norwegian Continental Shelf, characterization of the overburden formations indicated that a simplified permanent P&A strategy is possible based on a concept with annular sealing from ‘creeping’ Green Clay and a buffering capacity in the underlying Balder formation. Leak scenario simulations with a fracture growth simulator concluded that such a permanent P&A strategy is robust against deep gas migrating, given that a sufficient stress contrast is present between the sealing Green Clay and the Balder. Estimates of the stress profile in the overburden derived from sonic logs indicated such a favorable stress profile is present. However, this stress profile had to be confirmed by dedicated stress tests. Consequently, ‘Extended Leak Off Tests’ (XLOT) were planned and performed during the P&A operations in both the Balder and Green Clay.

The XLOT in the Balder formation was performed through perforations in the intermediate casing. However, as the Balder interval consisted of varying degrees of poorly bonded cement, this introduced a risk of uncertainty with regards to depth control—where the fracture(s) propagate and if there is communication to above or below the Balder formation.

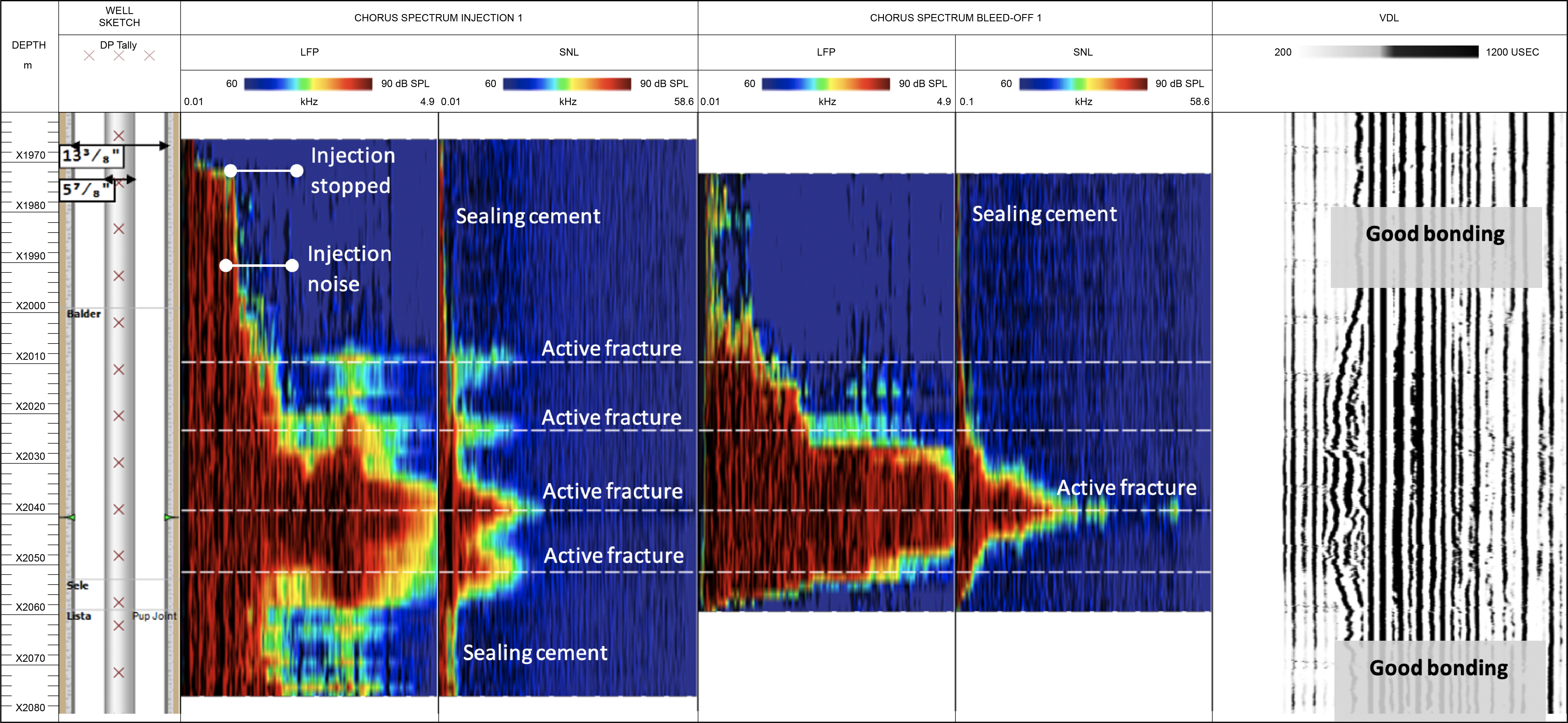

To mitigate this risk, the operator utilized TGT’s True Integrity system with Chorus acoustic technology, combined with downhole temperature and pressure sensors positioned close to the perforation depth. Chorus and its ‘Acoustic Power Spectrum’ was used to establish the injection/fracture point in the Balder during the XLOT and confirm the integrity of cemented casings above and below the Balder.

Deployed riglessly and through tubing, the Chorus Acoustic Spectrum enabled the induced flow classification (no flow, channeling in cement, and fracture flow) in the Balder formation and revealed the fracture initiation points behind the casing. It also confirmed there are no issues with cement seal integrity with accuracy of 15 psi/day pressure failure or 10 ml/min of leak rate.

The XLOT test conducted by the operator showed the main test output list can be extended in cases where Chorus acoustic monitoring is implemented. This case proved that the integration of the downhole data acquisition can be performed with no interference in the traditional XLOT program.

The Chorus Acoustic Power Spectrum visualizes active induced fractures and cement seal integrity behind the casing. The exact fracture depth can be determined and capacity analysis can be performed by monitoring the decay of the acoustic signal over time during the flowing-back stage. Cement sealing can be verified by interpretation of the acoustic signature recorded across the cement barrier.

The above-listed unique datasets can be used today by rock mechanics, well integrity, and well abandonment engineers.

With the right combination of technologies, good planning and execution, the operation was successful and results were confirmed, in addition to validating the sealing Green Clay intervals, a stress contrast of 11 points, and proving this new permanent P&A concept (details in SPE). This enabled the consideration of the shale barriers such as Balder for permanent P&A.

Decommissioning a well securely and permanently requires both an accurate P&A program and the use of alternative barriers to ensure long-term, sustainable integrity. It is essential to use proven verification techniques to inform the P&A program and validate the seal integrity of critical barriers.